Compare M5C vs K1 SE

Comparison between the best 3D printers

Choose the best 3D printer at the best price. The cheapest 3D printers are here.

Buy a 3D printer here with 3D Fila.

|

|

|

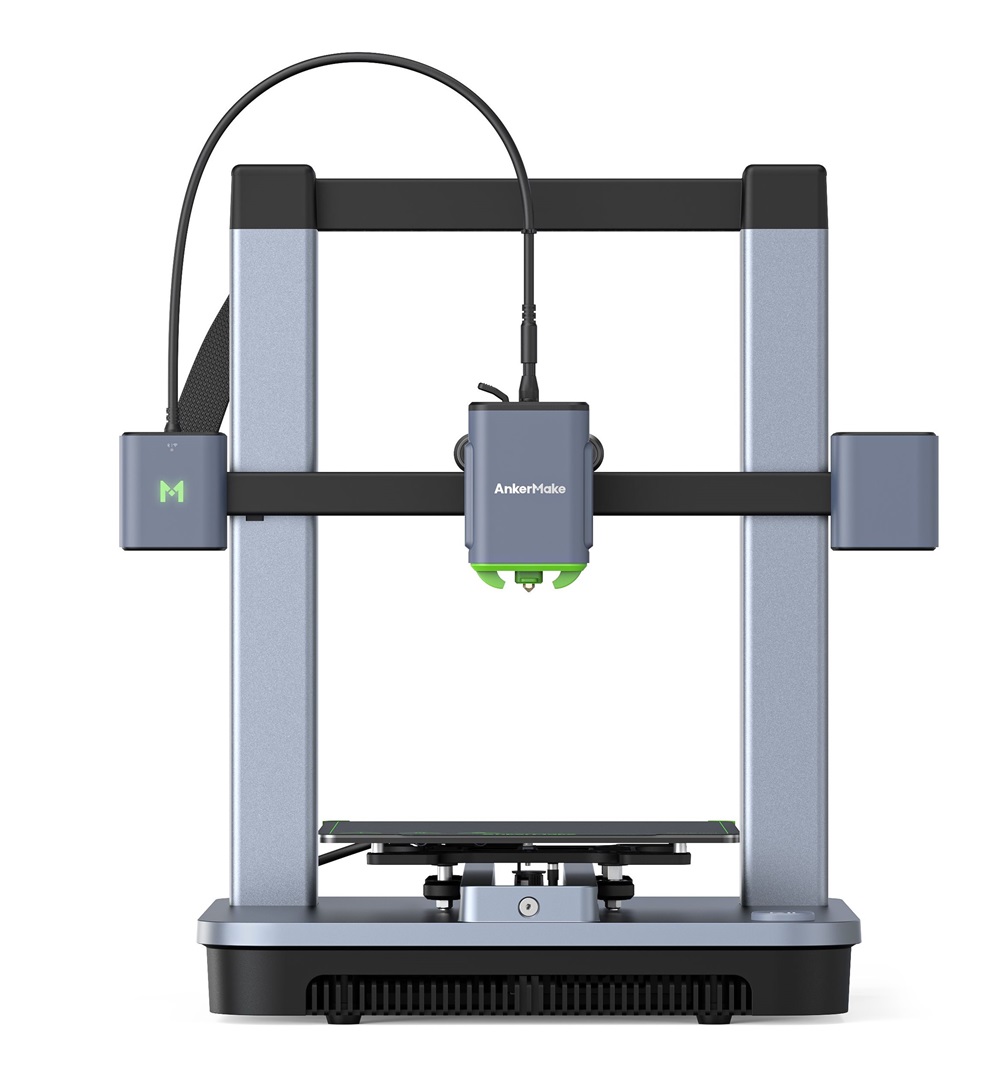

| Model | M5C[BUY M5C] |

K1 SE |

| Printing Material | Filament | Filament |

| Buy Filament for AnkerMake M5C | Buy Filament forCreality 3D K1 SE | |

| Estimated price | $399,00 | $349,00 |

| Manufacturer | AnkerMake | Creality 3D |

| Release Year | 2023 | 2023 |

| Print Volume [mm] | 220x220x250 | 220x220x250 |

| Printer Size [mm] | 466x374x480 | 355x355x480 |

| Weight [kg] | 9,6 | 10,24 |

| Power Loss Recovery | YES | YES |

| Enclosed printer | NO | NO |

| Bed Leveling | Automatic | Automatic |

| Filament End Sensor | YES | YES |

| Bed type | Heated | Heated |

| Power supply system | Direct Drive | Direct Drive |

| Standard nozzle | 0,4 | 0,4 |

| Maximum Nozzle Temperature [°C] | 300 | 300 |

| Maximum Bed Temperature [°C] | 100 | 100 |

| Maximum printing speed [mm/s] | 500 | 600 |

| Filament holder | YES | YES |

| Camera for supervision | NO | NO |

| Recommended filaments | PLA, PETG, TPU, ABS, PA, PLA-CF, PETG-CF, PA-CF | Hyper PLA, PLA, PETG, PET, TPU |

| Recommended slicers | AnkerMake Studio (macOS, Windows), Simplify3D, Ultimaker Cura, PrusaSlicer | Creality Print; Cura, Simplify3D e PrusaSlicer |

| Maximum Resolution [mm] | 0,1 | 0,1 |

| Processor | ||

| Display | Display touchscreen 4,3'' | |

| Power Supply | 350 W | 110/220V / 350W |

| Connectivity | Wi-Fi, USB-C, Bluetooth | Ethernet / USB / Wi-Fi |

| Operating systems | Windows, Linux e Macbook | Windows, Mac, Linux |

| Date of registration in the system | 2024-09-11 | 2023-08-26 |

| Release date | 2023 | 2023 |

| Extra features | The AnkerMake M5 printer stands out for its impressive print speed, reaching up to 500mm/s. It features AI print monitoring, an integrated camera for creating timelapses, auto-leveling bed with pressure sensor, direct extruder, flexible PEI-coated build plate, and Wi-Fi and USB-C connectivity. Assembly is quick and easy, and the printer is designed to deliver high print quality and ease of use. | The Creality K1 SE is a high-speed 3D printer with CoreXY system, capable of printing at up to 600mm/s with acceleration of 20000mm/s². It has a dual-gear extruder, easy-to-replace tri-metal nozzle, automatic leveling, and advanced features such as vibration reduction algorithms and intelligent operation. Its rigid cast aluminum frame ensures stability, while the open-source Klipper-based system offers freedom for customization. It is pre-assembled for a simplified and fast user experience. |

| Support for multiple colors and materials (AMS and CFS) | NO | NO |

Notes * |

||

| Cost-benefit | 7 / 10 | 7 / 10 |

| Hardware | 2.8 / 10 | 3.5 / 10 |

| Tela | . | . |

| Print volume | 3 / 10 | 3 / 10 |

| Performance | 4 / 10 | 5 / 10 |

| [BUY M5C] |

Conclusion |

| In comparing the AnkerMake M5C and the Creality 3D K1 SE, both printers share similar dimensions and specifications, including print volume and the types of filament they support. However, several distinctions emerge between the two, influencing their overall value to potential buyers. The AnkerMake M5C, priced slightly higher, impresses with its user-friendly features, such as AI print monitoring and a touchscreen interface for ease of use. Its print speed, while fast at 500mm/s, is notably lower than that of the K1 SE. The M5C's strengths lie in its ease of assembly and quick setup, making it a solid choice for those new to 3D printing or looking for convenience. Conversely, the Creality 3D K1 SE stands out with its superior maximum printing speed of 600mm/s and advanced hardware capabilities, including a dual-gear extruder and a robust aluminum frame. This printer is designed for users seeking speed and high-performance features, making it particularly attractive for those with more experience or specific rapid production needs. In summary, if you prioritize ease of use and user-friendly technology, the AnkerMake M5C may be more appealing despite its higher price. However, for those focused on performance and speed, the Creality 3D K1 SE offers substantial advantages, potentially justifying its slightly lower cost. Both models provide excellent cost-benefit ratios, ultimately allowing users to choose based on their specific requirements and expertise levels in 3D printing. |