Compare Toybox vs Comgrow T500

Comparison between the best 3D printers

Choose the best 3D printer at the best price. The cheapest 3D printers are here.

Buy a 3D printer here with 3D Fila.

|

|

|

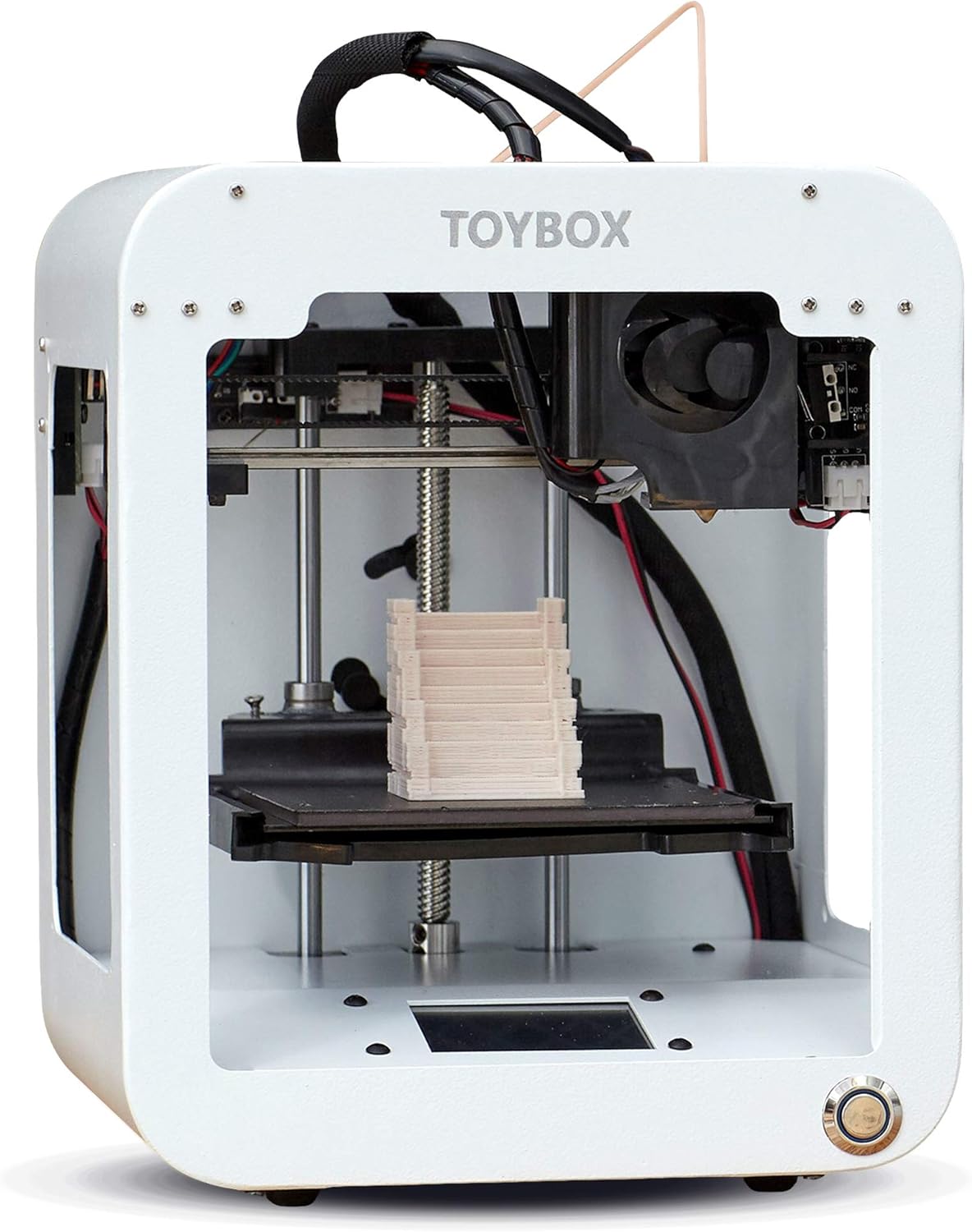

| Model | Toybox[BUY Toybox] |

Comgrow T500 |

| Printing Material | Filament | Filament |

| Buy Filament for Toybox Toybox | Buy Filament forSovol Comgrow T500 | |

| Estimated price | $299,00 | $799,00 |

| Manufacturer | Toybox | Sovol |

| Release Year | 2024 | 2024 |

| Print Volume [mm] | 70x80x90 | 500x500x500 |

| Printer Size [mm] | 190x190x230 | 817x810x962 |

| Weight [kg] | 3 | 39 |

| Power Loss Recovery | NO | YES |

| Enclosed printer | NO | NO |

| Bed Leveling | Manual | Automatic |

| Filament End Sensor | NO | YES |

| Bed type | Heated | |

| Power supply system | Direct Drive | Direct Drive |

| Standard nozzle | 0,5 | 0,4 |

| Maximum Nozzle Temperature [°C] | 210 | 300 |

| Maximum Bed Temperature [°C] | 80 | |

| Maximum printing speed [mm/s] | 60 | 500 |

| Filament holder | YES | YES |

| Camera for supervision | NO | NO |

| Recommended filaments | PLA | PLA, PETG, Fibra de Carbono, TPU |

| Recommended slicers | Toybox | Creality Print, Cura 5.0 ou superior, Prusa Slicer, Orca |

| Maximum Resolution [mm] | 0,2 | 0,1 |

| Processor | ||

| Display | Touchscreen 2,4'' | 7'' IPS touchscreen, 60Hz |

| Power Supply | 500 W | |

| Connectivity | Wi-fi | |

| Operating systems | iOS, Android | |

| Date of registration in the system | 2024-08-06 | 2024-07-18 |

| Release date | 2024 | 2024 |

| Extra features | The Toybox 3D printer is an excellent option for children and beginners. Easy to use, with intuitive setup and simplified operation via an app. The Toybox allows you to print thousands of toys and projects through a user-friendly interface. It has a removable magnetic table that makes it easy to remove printed objects. The filament is PLA, safe for children, and the printing is reliable and error-free. It also offers custom design options, allowing you to create and print drawings and photos. | The Sovol Comgrow T500 stands out for its large print volume of 500x500x500 mm, ideal for large-scale projects. It has a direct extruder with a gear ratio of 6.5:1, speeds of up to 200 mm/s, and high-performance motors. The 7" touchscreen with Klipper software makes navigation easy. The 49-point automatic leveling ensures a perfect first layer. It also has a full metal hotend at 300°C, linear rails on all axes, and WiFi connectivity. |

| Support for multiple colors and materials (AMS and CFS) | NO | NO |

Notes * |

||

| Cost-benefit | 6 / 10 | 7 / 10 |

| Hardware | 0.8 / 10 | 3.2 / 10 |

| Tela | . | . |

| Print volume | 3 / 10 | 5 / 10 |

| Performance | 0 / 10 | 4 / 10 |

| [BUY Toybox] |

Conclusion |

| In comparing the Toybox and the Comgrow T500 3D printers, it is clear that each model caters to distinct user needs and preferences. The Toybox, priced more affordably, is specifically designed for children and beginners. Its compact size, user-friendly touchscreen interface, and reliance on PLA filament make it an excellent choice for casual users hoping to create simple projects. The focus on ease-of-use, along with features like a removable magnetic build plate, enhances its appeal for those new to 3D printing. However, its limited print volume and lack of advanced features such as automatic bed leveling and filament sensors may restrict its capabilities for more serious enthusiasts. Conversely, the Comgrow T500 positions itself as a more advanced, versatile machine suited for hobbyists and professionals. Its larger print volume and ability to accommodate a wider range of materials, including complex filaments like carbon fiber and TPU, significantly expand the scope of potential projects. The incorporation of features like automatic bed leveling, a higher maximum nozzle temperature, and robust construction offers improved reliability and performance, making it a strong contender for larger-scale creations. In terms of cost-effectiveness, while the Toybox offers accessibility and ease of use, the Comgrow T500 provides a more capable platform for those willing to invest more for enhanced performance and features. Ultimately, the choice between these printers boils down to the intended use: the Toybox for beginners seeking straightforward fun and learning, and the Comgrow T500 for users looking for high performance and versatility in their 3D printing endeavors. |