Compare Kobra vs A3V3

Comparison between the best 3D printers

Choose the best 3D printer at the best price. The cheapest 3D printers are here.

Buy a 3D printer here with 3D Fila.

|

|

|

| Model | Kobra |

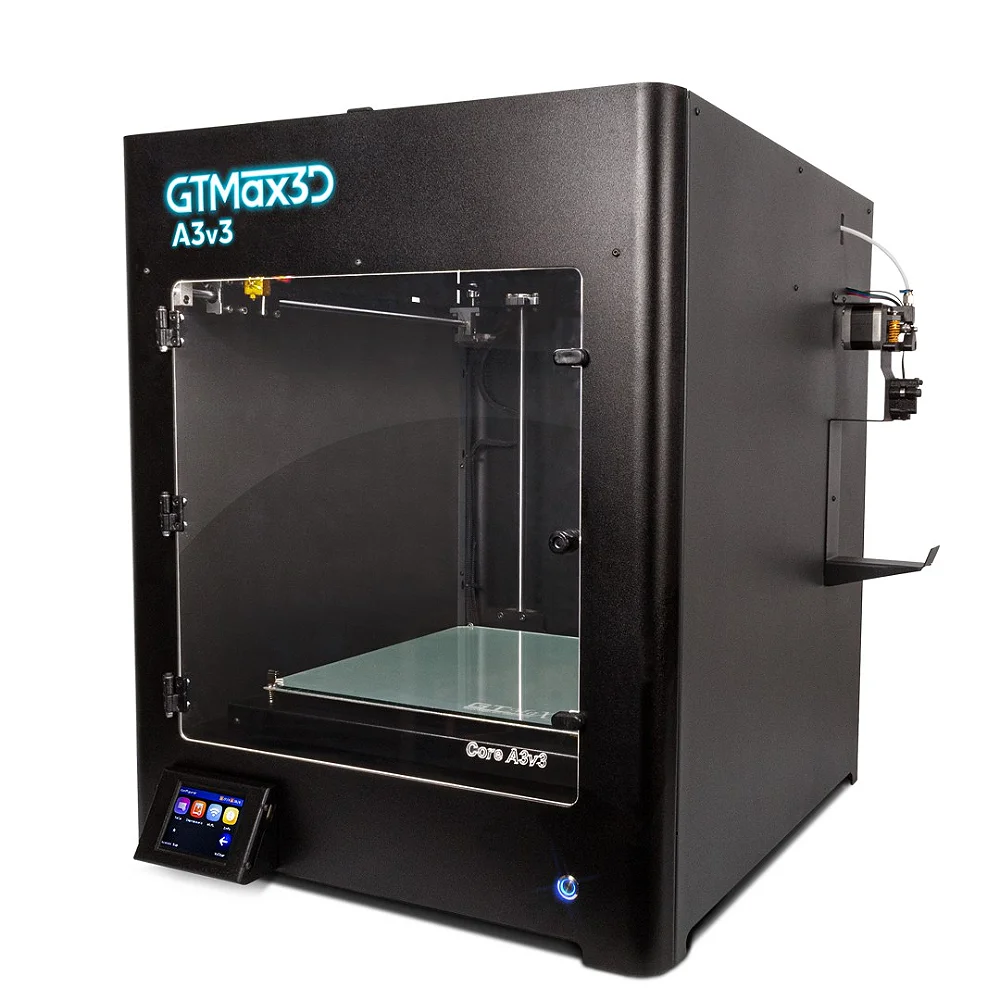

A3V3 |

| Printing Material | Filament | Filament |

| Buy Filament for Anycubic Kobra | Buy Filament forGTMax A3V3 | |

| Estimated price | $259,00 | $1210,00 |

| Manufacturer | Anycubic | GTMax |

| Release Year | 2022 | 2022 |

| Print Volume [mm] | 220x220x250 | 320x320x340 |

| Printer Size [mm] | 486x430x486 | 640x580x630 |

| Weight [kg] | 7 | |

| Power Loss Recovery | YES | YES |

| Enclosed printer | NO | YES |

| Bed Leveling | Automatic | Automatic |

| Filament End Sensor | NO | YES |

| Bed type | Heated | Heated |

| Power supply system | Direct Drive | Bowden |

| Standard nozzle | 0,4 | 0,4 |

| Maximum Nozzle Temperature [°C] | 260 | 295 |

| Maximum Bed Temperature [°C] | 110 | |

| Maximum printing speed [mm/s] | 180 | 180 |

| Filament holder | YES | YES |

| Camera for supervision | NO | NO |

| Recommended filaments | PLA, PETG, Tritan, Flex, ABS | PLA, PETG |

| Recommended slicers | Cura, Simplify, Slic3r, IdeaMaker | Cura, Simplify, Slic3r, IdeaMaker e outros |

| Maximum Resolution [mm] | 0,1 | 0,05 |

| Processor | ||

| Display | Display touchscreen 4,3'' | Display touchscreen 3,2'' |

| Power Supply | 110/220V / 400W | |

| Connectivity | SD / USB | SD / USB / Wi-Fi |

| Operating systems | Windows, Mac, Linux | Windows, Mac, Linux |

| Date of registration in the system | 2022-11-09 | 2022-11-12 |

| Release date | 2022 | 2022 |

| Extra features | The Anycubic Kobra features automatic bed leveling and a direct extruder for easy filament handling. The print bed is coated with PEI on a flexible steel plate, improving adhesion and making prints easier to remove. The printer features sensorless homing and is designed to be easily disassembled for easy maintenance and customization. | The PROCORE A3v3 is an advanced 3D printer with a robust structure and Wi-Fi connectivity. It stands out for its aluminum extruder with Dual Gear system for precision and traction, and a movement system with machined parts. It includes a 3.2-inch LCD Touchscreen Display, Wi-Fi remote control and a Core XY movement system for greater speed and precision. It offers an Allmetal Volcano hotend that reaches up to 295°C, is compatible with various filaments and has an energy saving system, reducing consumption by up to 75%. |

| Support for multiple colors and materials (AMS and CFS) | NO | NO |

Notes * |

||

| Cost-benefit | 7 / 10 | 6 / 10 |

| Hardware | 1.8 / 10 | 3 / 10 |

| Tela | . | . |

| Print volume | 3 / 10 | 4 / 10 |

| Performance | 1 / 10 | 1 / 10 |

Conclusion |

| In comparing the Anycubic Kobra and the GTMax A3V3, clear distinctions emerge regarding their features, capabilities, and overall value proposition. The Anycubic Kobra, priced significantly lower, caters especially well to hobbyists and those new to 3D printing. It offers essential features like automatic bed leveling, a direct drive system for better filament management, and a heated bed. Its compact print volume makes it suitable for smaller projects, and the user-friendly design includes a PEI-coated flexible steel plate to facilitate easier print removal. However, it lacks advanced features such as Wi-Fi connectivity and a filament end sensor. Conversely, the GTMax A3V3, despite its higher price, presents a more robust structure and a larger print volume, making it ideal for larger and more intricate projects. Its dual gear aluminum extruder enhances precision, and the all-metal Volcano hotend allows for a broader range of filament compatibility. Additional features, such as Wi-Fi connectivity and a more refined touchscreen interface, add to its appeal for users who prioritize advanced functionality. Ultimately, the choice between these two printers should align with the user's specific needs and budget. For those seeking a cost-effective, reliable machine for general use, the Anycubic Kobra is an excellent choice. Conversely, if one's focus is on larger prints and advanced features, the GTMax A3V3 justifies its higher price with enhanced capabilities. Thus, each printer serves distinct purposes, catering to different segments of the 3D printing market. |