Compare K1 Max vs A1

Comparison between the best 3D printers

Choose the best 3D printer at the best price. The cheapest 3D printers are here.

Buy a 3D printer here with 3D Fila.

|

|

|

| Model | K1 Max[BUY K1 Max] |

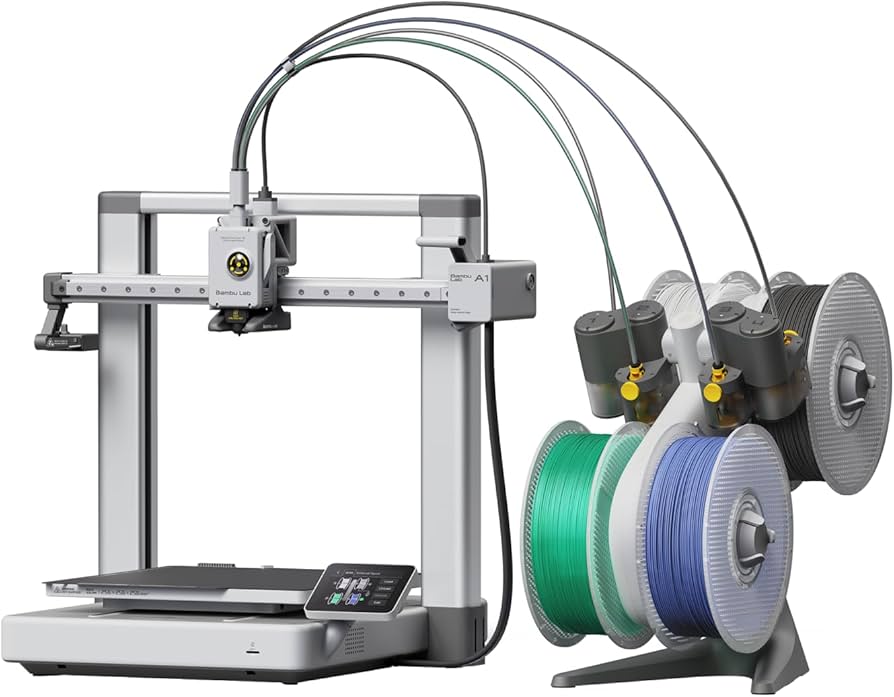

A1[BUY A1] |

| Printing Material | Filament | Filament |

| Buy Filament for Creality 3D K1 Max | Buy Filament forBambu Lab A1 | |

| Estimated price | $1300,00 | $700,00 |

| Manufacturer | Creality 3D | Bambu Lab |

| Release Year | 2023 | 2023 |

| Print Volume [mm] | 300x300x300 | 256x256x256 |

| Printer Size [mm] | 435x462x526 | 385x410x430 |

| Weight [kg] | 18 | 8,3 |

| Power Loss Recovery | YES | YES |

| Enclosed printer | YES | NO |

| Bed Leveling | Automatic | Automatic |

| Filament End Sensor | YES | YES |

| Bed type | Heated | Heated |

| Power supply system | Direct Drive | Direct Drive |

| Standard nozzle | 0,4 | 0,4 |

| Maximum Nozzle Temperature [°C] | 300 | 300 |

| Maximum Bed Temperature [°C] | 100 | 100 |

| Maximum printing speed [mm/s] | 600 | 500 |

| Filament holder | YES | YES |

| Camera for supervision | YES | YES |

| Recommended filaments | ABS, PLA, PETG, TPU, PA, ASA, PC, PLA-CF, PA-CF, PET-CF | PLA, PETG, TPU, PVA |

| Recommended slicers | Creality Print, Cura, Simplify, Slic3r, IdeaMaker e outros | SuperSlicer, PrusaSlicer, Cura, OrcaSlicer |

| Maximum Resolution [mm] | 0,1 | 0,1 |

| Processor | ||

| Display | Display touchscreen 4,3'' | Touchscreen 3,5 |

| Power Supply | 350 W | |

| Connectivity | USB / Wi-Fi / Ethernet | Wi-Fi, Bambu-Bus, Cartão Micro SD |

| Operating systems | Windows, Mac, Linux | Windows, Linux, Macbook |

| Date of registration in the system | 2023-12-01 | 2024-07-17 |

| Release date | 2023 | 2023 |

| Extra features | The Creality K1 Max stands out as a fast Core XY 3D printer with a large build volume of 300 x 300 x 300 mm. It is fully enclosed and equipped with AI sensors to prevent print failures. This model has a smooth and flexible PEI build platform, and uses an automatic leveling system with LIDAR, as well as a filament run-out sensor. LAN, Creality Cloud and USB Flash Disk connectivity are available, as well as a 4.3-inch touchscreen interface. The K1 Max is robust, weighing in at 18 kg, and includes an AI camera and limited version of the Klipper firmware. Its motion system is solid and the printer is efficient with high-temperature filaments, but it is not silent. Assembly is 99% complete, requiring only minor adjustments before use. | The BambuLab A1 printer features fully automatic calibration, multi-color printing with the AMS system, active flow rate compensation, quick nozzle change with a clip, active motor noise cancellation, a build volume of 256x256x256 mm³, a maximum extruder temperature of 300°C, and a heated bed of up to 100°C. In addition, it has high precision, a machine health management system and an intuitive 3.5-inch touchscreen interface. |

| Support for multiple colors and materials (AMS and CFS) | NO | YES |

Notes * |

||

| Cost-benefit | 7 / 10 | 7 / 10 |

| Hardware | 4.8 / 10 | 4.8 / 10 |

| Tela | . | . |

| Print volume | 4 / 10 | 4 / 10 |

| Performance | 5 / 10 | 4 / 10 |

| [BUY K1 Max] | [BUY A1] |

Conclusion |

| In comparing the Creality K1 Max and the Bambu Lab A1, both printers offer impressive features tailored for different needs and preferences. The K1 Max excels in print volume, offering a larger build area and advanced features geared towards high-temperature filaments, making it a robust choice for serious enthusiasts. Its enclosed design enhances print stability and safety, while the use of AI sensors and a comprehensive connectivity suite adds considerable value for users looking for reliability in their prints. On the other hand, the Bambu Lab A1 is notably lighter, more compact, and offers unique capabilities such as automatic color switching and motor noise cancellation, catering to users interested in versatility and ease of use in their printing experience. Its calibration and health management systems also make it an attractive option for those who prioritize precision and user-friendliness. While the K1 Max is priced at a premium due to its larger volume and advanced features, the A1 provides an excellent balance of performance and cost, making it a more budget-friendly option without significantly compromising quality. Ultimately, the decision between the two will depend on specific user needs, such as desired print volume, material versatility, and budget considerations. |