Compare Ender 7 vs CR 10 Smart

Comparison between the best 3D printers

Choose the best 3D printer at the best price. The cheapest 3D printers are here.

Buy a 3D printer here with 3D Fila.

|

|

|

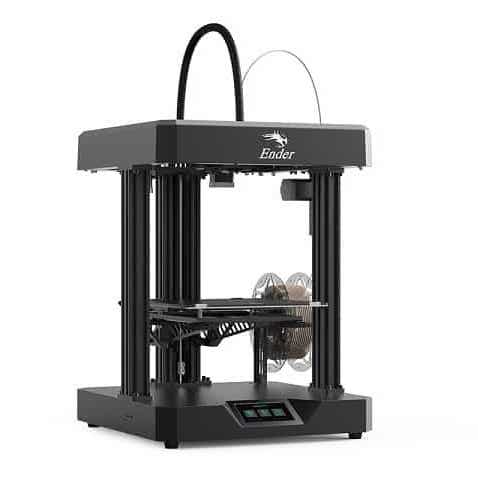

| Model | Ender 7[BUY Ender 7] |

CR 10 Smart[BUY CR 10 Smart] |

| Printing Material | Filament | Filament |

| Buy Filament for Creality 3D Ender 7 | Buy Filament forCreality 3D CR 10 Smart | |

| Estimated price | $429,00 | $520,00 |

| Manufacturer | Creality 3D | Creality 3D |

| Release Year | 2021 | 2021 |

| Print Volume [mm] | 250x250x300 | 300x300x400 |

| Printer Size [mm] | 430x460x570 | 578x522x648 |

| Weight [kg] | 17,2 | 14 |

| Power Loss Recovery | YES | YES |

| Enclosed printer | NO | NO |

| Bed Leveling | Manual | Automatic |

| Filament End Sensor | YES | YES |

| Bed type | Heated | Heated |

| Power supply system | Bowden | Bowden |

| Standard nozzle | 0,4 | 0,4 |

| Maximum Nozzle Temperature [°C] | 260 | 260 |

| Maximum Bed Temperature [°C] | 100 | 100 |

| Maximum printing speed [mm/s] | 250 | 200 |

| Filament holder | YES | YES |

| Camera for supervision | NO | NO |

| Recommended filaments | PLA, PETG, Tritan, Flex, ABS | PLA, PETG, Tritan, Flex, ABS |

| Recommended slicers | Cura, Simplify, Slic3r, IdeaMaker | Cura, Simplify, Slic3r, IdeaMaker |

| Maximum Resolution [mm] | 0,1 | 0,1 |

| Processor | Creality CR-FDM V.2.4.S1_V101 32bits | Processador ARM STM32F103 RET6 CPU |

| Display | Display touchscreen 4,3'' | Display touchscreen 4,3'' |

| Power Supply | 110/220V / 350W | 110/220V / 350W |

| Connectivity | SD / USB | SD / USB / Wi-Fi |

| Operating systems | Windows, Mac, Linux | Windows, Mac, Linux |

| Date of registration in the system | 2022-11-04 | 2022-11-04 |

| Release date | 2021 | 2021 |

| Extra features | Crealitys Ender 7 printer offers remarkable print speeds, utilizing CoreXY kinematics for precise and fast movement. With a 250x250x300mm build area, dual direct extruder, and custom hotend, the Ender 7 is capable of printing at high speeds, although quality may suffer on smaller prints. Assembly is relatively straightforward, but the machine is noisy and can get hot. Its true speed potential is most noticeable on larger prints, where it outperforms its competitors. | The Creality CR-10 Smart stands out for its stability, with a dual Z axis and additional supports, minimizing oscillation in high prints. Its redesigned hotend offers better cooling, expanding the range of usable materials. The glass printing surface, with automatic leveling, facilitates the adhesion and removal of parts. Includes Wi-Fi / LAN connection and automatic shutdown after printing, adding convenience and efficiency. It features an effective single-gear extruder and an intuitive touchscreen interface, despite some firmware issues. |

| Support for multiple colors and materials (AMS and CFS) | NO | NO |

Notes * |

||

| Cost-benefit | 7 / 10 | 6 / 10 |

| Hardware | 2 / 10 | 2 / 10 |

| Tela | . | . |

| Print volume | 4 / 10 | 4 / 10 |

| Performance | 2 / 10 | 2 / 10 |

| [BUY Ender 7] | [BUY CR 10 Smart] |

Conclusion |

| In conclusion, both the Ender 7 and CR-10 Smart are solid options for those looking to invest in a 3D printer from Creality within the same release year. While the Ender 7 is priced more affordably, it boasts higher maximum printing speeds and an efficient build area suitable for larger projects. However, prospective users should be aware that rapid printing may compromise the quality of smaller details. On the other hand, the CR-10 Smart, despite its higher price point, presents advantages in terms of stability and ease of use, thanks to features like automatic bed leveling and enhanced cooling capabilities. This printer may be particularly appealing for users who prioritize consistent print quality and convenience, given its superior support for material versatility and a more sophisticated user interface. Ultimately, the choice between the two comes down to specific user needs: if speed and a larger build volume are the focus, the Ender 7 is the budget-friendly option. Conversely, if ease of use and stability are paramount, the CR-10 Smart justifies its higher price with additional features that enhance the printing experience. Both models reflect solid engineering, allowing users to produce high-quality prints across various materials. |