Compare Ender 6 vs Kobra S1 Combo

Comparison between the best 3D printers

Choose the best 3D printer at the best price. The cheapest 3D printers are here.

Buy a 3D printer here with 3D Fila.

|

|

|

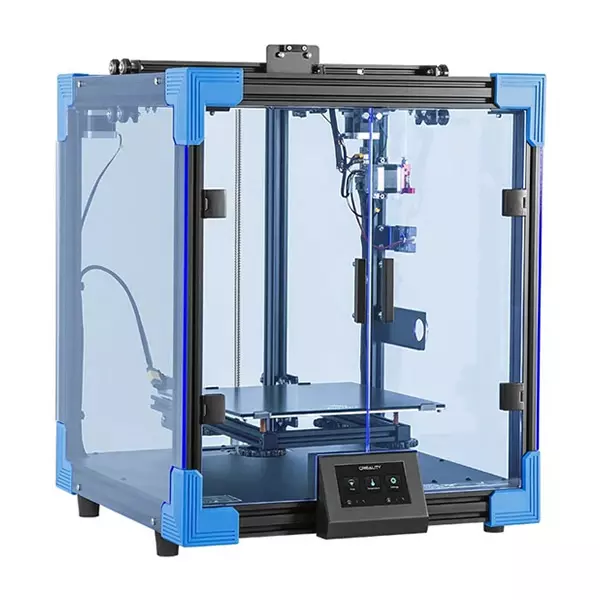

| Model | Ender 6[BUY Ender 6] |

Kobra S1 Combo[BUY Kobra S1 Combo] |

| Printing Material | Filament | Filament |

| Buy Filament for Creality 3D Ender 6 | Buy Filament forAnycubic Kobra S1 Combo | |

| Estimated price | $499,00 | $599,00 |

| Manufacturer | Creality 3D | Anycubic |

| Release Year | 2020 | 2025 |

| Print Volume [mm] | 250x250x400 | 250x250x250 |

| Printer Size [mm] | 495x495x650 | 400x410x490 |

| Weight [kg] | 22 | 18 |

| Power Loss Recovery | YES | YES |

| Enclosed printer | YES | YES |

| Bed Leveling | Manual | Automatic |

| Filament End Sensor | YES | YES |

| Bed type | Heated | Heated |

| Power supply system | Bowden | Direct Drive |

| Standard nozzle | 0,4 | 0,4 |

| Maximum Nozzle Temperature [°C] | 260 | 320 |

| Maximum Bed Temperature [°C] | 100 | 120 |

| Maximum printing speed [mm/s] | 150 | 600 |

| Filament holder | YES | YES |

| Camera for supervision | NO | NO |

| Recommended filaments | PLA, TPU, ABS, PETG | PLA, PETG, TPU[1], ABS, ASA |

| Recommended slicers | Cura, Simplify, Slic3r | Anycubic Slicer Next, Orca Slicer |

| Maximum Resolution [mm] | 0,1 | 0,01 |

| Processor | 32 bits | |

| Display | Touchscreen TFT 4,3'' | Touchscreen 4,3'' |

| Power Supply | 24V / 504W | |

| Connectivity | SD / USB | USB, Wifi |

| Operating systems | Windows, Mac, Linux | Windows, Linux e Macbook |

| Date of registration in the system | 2021-04-15 | 2025-02-25 |

| Release date | 2020 | 2025 |

| Extra features | The Creality Ender 6 stands out in the world of 3D printers with its CoreXY system, offering fast and high-quality prints. With a robust design, it has acrylic panels to protect against air currents, optimizing the printing of materials that require higher temperatures. It features a generic Creality hotend, effective up to ~240°C. Its differentials include 10mm GATES belts, promoting stability at high speeds, and a 360W power supply for reliable performance. The machine also has an intuitive user interface through a 4.3-inch touchscreen. | The Anycubic Kobra S1 Combo is a fully enclosed CoreXY 3D printer with speeds up to 600mm/s and 20,000mm/s² acceleration. It features a 320°C hotend, native multicolor printing (4 to 8 colors with ACE Pro), and active filament drying. Equipped with LeviQ 3.0 auto-leveling, camera monitoring, AI failure detection, carbon filtration, and a 4.3 touchscreen, it ensures high-quality, efficient, and reliable 3D printing. |

| Support for multiple colors and materials (AMS and CFS) | NO | YES |

Notes * |

||

| Cost-benefit | 7 / 10 | 7 / 10 |

| Hardware | 2.5 / 10 | 7.2 / 10 |

| Tela | . | . |

| Print volume | 4 / 10 | 3 / 10 |

| Performance | 1 / 10 | 5 / 10 |

| [BUY Ender 6] | [BUY Kobra S1 Combo] |

Conclusion |

| In comparing the Ender 6 by Creality 3D and the Kobra S1 Combo by Anycubic, both 3D printers showcase distinct advantages and cater to different user preferences. The Ender 6, despite being released in 2020, offers a solid build with its enclosed design, decent print volume, and reliability at relatively lower speeds. Its manual bed leveling might be a drawback for some users who prefer more automation, but it still provides quality prints at competitive speeds for its price bracket. The Ender 6 excels in robust construction and stability, making it a practical choice for hobbyists who appreciate hands-on assembly and tuning. On the other hand, the Kobra S1 Combo, released in 2025, significantly ramps up features with advanced capabilities such as automatic bed leveling, a higher maximum nozzle and bed temperature, and impressive print speeds that can dramatically cut down printing time. With features supporting multicolor printing and enhanced AI monitoring for failure detection, it is geared towards users looking for cutting-edge technology and versatility in materials. The direct drive system also allows better handling of flexible filaments compared to the Ender 6. While the Ender 6 may cater to those seeking reliable, cost-effective capabilities with a traditional approach, the Kobra S1 Combo is aimed at tech-savvy users wanting high-performance features and faster production times. Ultimately, the choice between the two should depend on individual printing needs, budget considerations, and the level of automation desired in the printing process. |