Compare Ender 5 Max vs Kobra

Comparison between the best 3D printers

Choose the best 3D printer at the best price. The cheapest 3D printers are here.

Buy a 3D printer here with 3D Fila.

|

|

|

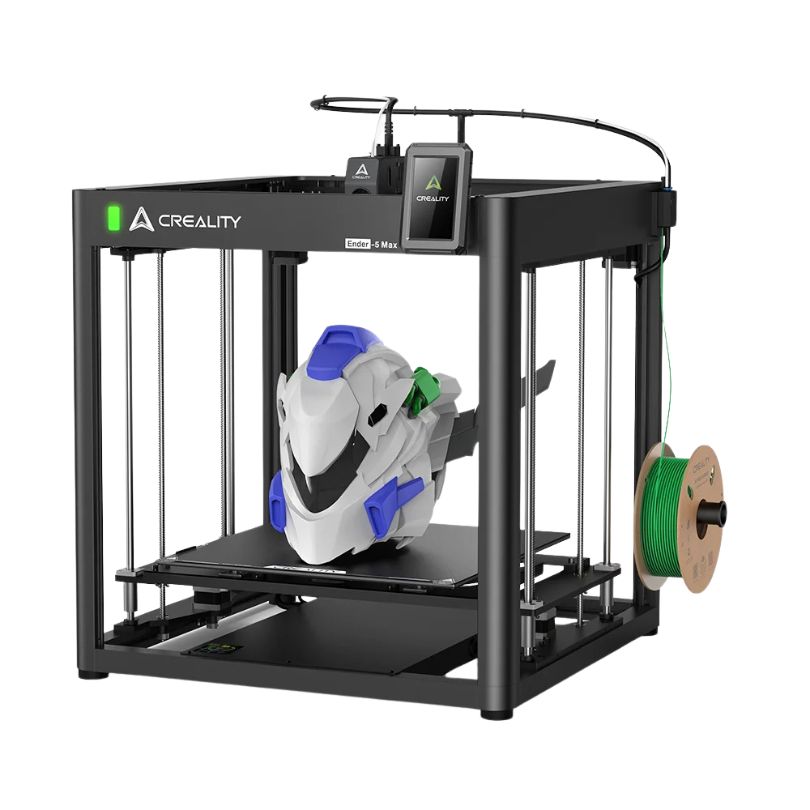

| Model | Ender 5 Max |

Kobra |

| Printing Material | Filament | Filament |

| Buy Filament for Creality Ender 5 Max | Buy Filament forAnycubic Kobra | |

| Estimated price | $769,00 | $259,00 |

| Manufacturer | Creality | Anycubic |

| Release Year | 2025 | 2022 |

| Print Volume [mm] | 400x400x400 | 220x220x250 |

| Printer Size [mm] | 649x721x850 | 486x430x486 |

| Weight [kg] | 25,9 | 7 |

| Power Loss Recovery | YES | YES |

| Enclosed printer | NO | NO |

| Bed Leveling | Automatic | Automatic |

| Filament End Sensor | YES | NO |

| Bed type | Heated | Heated |

| Power supply system | Direct Drive | Direct Drive |

| Standard nozzle | 0,4 | 0,4 |

| Maximum Nozzle Temperature [°C] | 300 | 260 |

| Maximum Bed Temperature [°C] | 100 | 110 |

| Maximum printing speed [mm/s] | 700 | 180 |

| Filament holder | YES | YES |

| Camera for supervision | YES | YES |

| Recommended filaments | Hyper PLA/PLA/PETG/TPU95A/ABS/ASA/PLA-CF/PA/PLA-Silk | PLA, PETG, Tritan, Flex, ABS |

| Recommended slicers | Creality Print 5.1 | Cura, Simplify, Slic3r, IdeaMaker |

| Maximum Resolution [mm] | 0,1 | 0,1 |

| Processor | ||

| Display | Touchscreen 4,3'' | Display touchscreen 4,3'' |

| Power Supply | 1250 W | 110/220V / 400W |

| Connectivity | USB, Wifi | SD / USB |

| Operating systems | Windows | Windows, Mac, Linux |

| Date of registration in the system | 2025-02-18 | 2022-11-09 |

| Release date | 2025 | 2022 |

| Extra features | The Ender 5 Max by Creality features a 400 x 400 x 400 mm build volume, a rigid aluminum frame, and 36-point auto bed leveling. With speeds up to 700 mm/s, it boasts a hardened dual-gear extruder and a 1000W heated bed, reaching 80°C in just 200 seconds. It supports remote management via WLAN, a tri-color status indicator, and quiet operation, making it ideal for high-precision, high-productivity 3D printing. | The Anycubic Kobra features automatic bed leveling and a direct extruder for easy filament handling. The print bed is coated with PEI on a flexible steel plate, improving adhesion and making prints easier to remove. The printer features sensorless homing and is designed to be easily disassembled for easy maintenance and customization. |

| Support for multiple colors and materials (AMS and CFS) | NO | NO |

Notes * |

||

| Cost-benefit | 7 / 10 | 7 / 10 |

| Hardware | 4.5 / 10 | 1.8 / 10 |

| Tela | . | . |

| Print volume | 4 / 10 | 3 / 10 |

| Performance | 6 / 10 | 1 / 10 |

Conclusion |

| In comparing the Ender 5 Max by Creality and the Anycubic Kobra, several key factors influence their respective value propositions beyond just price. The Ender 5 Max stands out with its impressive build volume of 400x400x400 mm, making it more suitable for larger projects. Its high maximum printing speed of 700 mm/s, along with features like a hardened dual-gear extruder and efficient heated bed, highlight its capability for high-precision and high-production tasks. The inclusion of features such as a filament end sensor, camera supervision, and a robust power supply adds to its appeal for professional users seeking reliability and efficiency. On the other hand, the Anycubic Kobra offers a more accessible price point while also providing essential features like automatic bed leveling and a direct drive system. While its print volume and speed are lower compared to the Ender 5 Max, it still caters well to hobbyists and those new to 3D printing, thanks to its easy maintenance and user-friendly design. Ultimately, the choice between these two printers heavily depends on the user's specific needs. For serious makers and professionals requiring a larger build volume and higher speeds, the Ender 5 Max justifies its higher price. Conversely, for hobbyists or individuals looking for a budget-friendly option that still delivers quality, the Anycubic Kobra is a commendable choice. Both printers display a suitable balance of cost-to-benefit, catering to different segments of the 3D printing market effectively. |