Compare Ender 5 Max vs KP3S PRO V2

Comparison between the best 3D printers

Choose the best 3D printer at the best price. The cheapest 3D printers are here.

Buy a 3D printer here with 3D Fila.

|

|

|

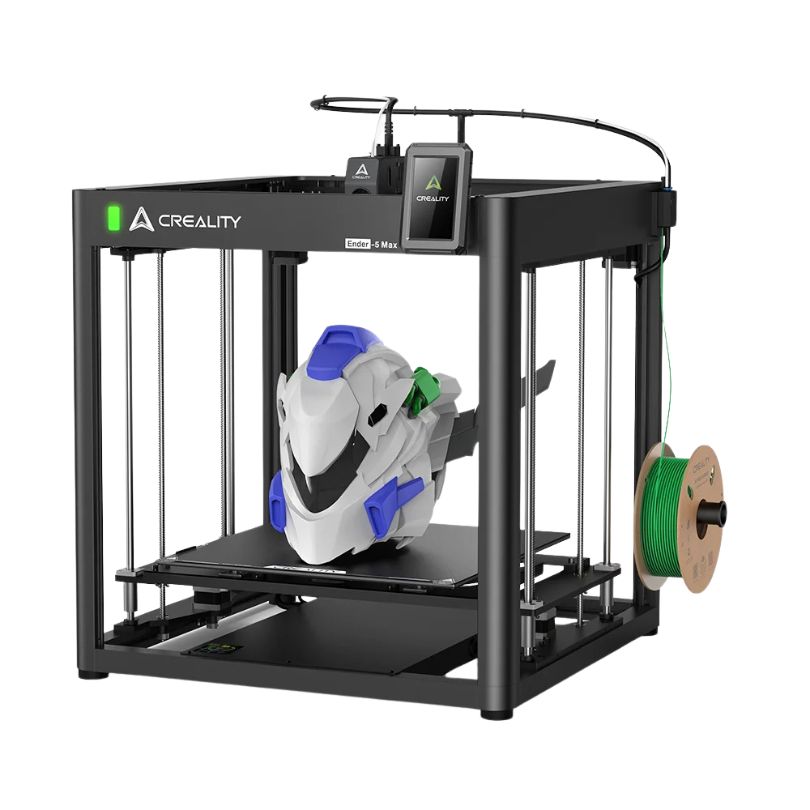

| Model | Ender 5 Max |

KP3S PRO V2 |

| Printing Material | Filament | Filament |

| Buy Filament for Creality Ender 5 Max | Buy Filament forKingroon KP3S PRO V2 | |

| Estimated price | $769,00 | $229,00 |

| Manufacturer | Creality | Kingroon |

| Release Year | 2025 | 2024 |

| Print Volume [mm] | 400x400x400 | 220x220x250 |

| Printer Size [mm] | 649x721x850 | 420x400x450 |

| Weight [kg] | 25,9 | 12,6 |

| Power Loss Recovery | YES | NO |

| Enclosed printer | NO | NO |

| Bed Leveling | Automatic | Automatic |

| Filament End Sensor | YES | NO |

| Bed type | Heated | Heated |

| Power supply system | Direct Drive | Direct Drive |

| Standard nozzle | 0,4 | 0,4 |

| Maximum Nozzle Temperature [°C] | 300 | 260 |

| Maximum Bed Temperature [°C] | 100 | 100 |

| Maximum printing speed [mm/s] | 700 | 350 |

| Filament holder | YES | YES |

| Camera for supervision | YES | YES |

| Recommended filaments | Hyper PLA/PLA/PETG/TPU95A/ABS/ASA/PLA-CF/PA/PLA-Silk | PLA, PETG, TPU |

| Recommended slicers | Creality Print 5.1 | Cura, Orca Slicer |

| Maximum Resolution [mm] | 0,1 | 0,01 |

| Processor | ||

| Display | Touchscreen 4,3'' | LCD Mono |

| Power Supply | 1250 W | 300 W |

| Connectivity | USB, Wifi | USB-C / MicroSD / Ethernet |

| Operating systems | Windows | Windows, Mac, Linux |

| Date of registration in the system | 2025-02-18 | 2025-03-18 |

| Release date | 2025 | 2024 |

| Extra features | The Ender 5 Max by Creality features a 400 x 400 x 400 mm build volume, a rigid aluminum frame, and 36-point auto bed leveling. With speeds up to 700 mm/s, it boasts a hardened dual-gear extruder and a 1000W heated bed, reaching 80°C in just 200 seconds. It supports remote management via WLAN, a tri-color status indicator, and quiet operation, making it ideal for high-precision, high-productivity 3D printing. | The Kingroon KP3S Pro V2 is a high-speed FDM 3D printer with Klipper firmware, ensuring fast and precise prints. It features linear rails on all axes, a Direct Drive extruder with a 9.5:1 gear ratio, and an efficient ceramic heater. It includes an inductive sensor for automatic bed leveling, a PEI magnetic bed, a built-in accelerometer for vibration calibration, and Wi-Fi, Ethernet, and USB connectivity for remote control. |

| Support for multiple colors and materials (AMS and CFS) | NO | NO |

Notes * |

||

| Cost-benefit | 7 / 10 | 7 / 10 |

| Hardware | 4.5 / 10 | 0.8 / 10 |

| Tela | . | . |

| Print volume | 4 / 10 | 3 / 10 |

| Performance | 6 / 10 | 3 / 10 |

Conclusion |

| In comparing the Ender 5 Max and the KP3S PRO V2, several key factors highlight the strengths and weaknesses of each printer, catering to different user needs and preferences. The Ender 5 Max, with its larger build volume and higher maximum printing speed, is designed for users seeking to create larger and more complex prints quickly. It is equipped with advanced features such as power loss recovery, a filament end sensor, and a higher maximum nozzle temperature, making it suitable for a wider range of materials and projects. The rugged build and robust hardware contribute to its reliability and precision, making it a solid choice for professional or serious hobbyist use. In contrast, the KP3S PRO V2 offers a more affordable option without compromising too much on performance. While it has a smaller build volume and slightly lower maximum printing speed, it incorporates features such as Klipper firmware for enhanced printing efficiency and a lightweight design for easier portability. The KP3S PRO V2 caters well to casual users or those who prioritize a budget-friendly 3D printer that still provides quality results. Ultimately, the best choice will depend on user requirements. If larger projects and advanced features are critical, the Ender 5 Max may be worth the investment. However, for those looking to explore 3D printing without a significant financial commitment, the KP3S PRO V2 represents a great entry point. Each printer has its own set of strengths that will appeal to different segments of the 3D printing community. |