Compare Ender 3 V3 vs H2D

Comparison between the best 3D printers

Choose the best 3D printer at the best price. The cheapest 3D printers are here.

Buy a 3D printer here with 3D Fila.

|

|

|

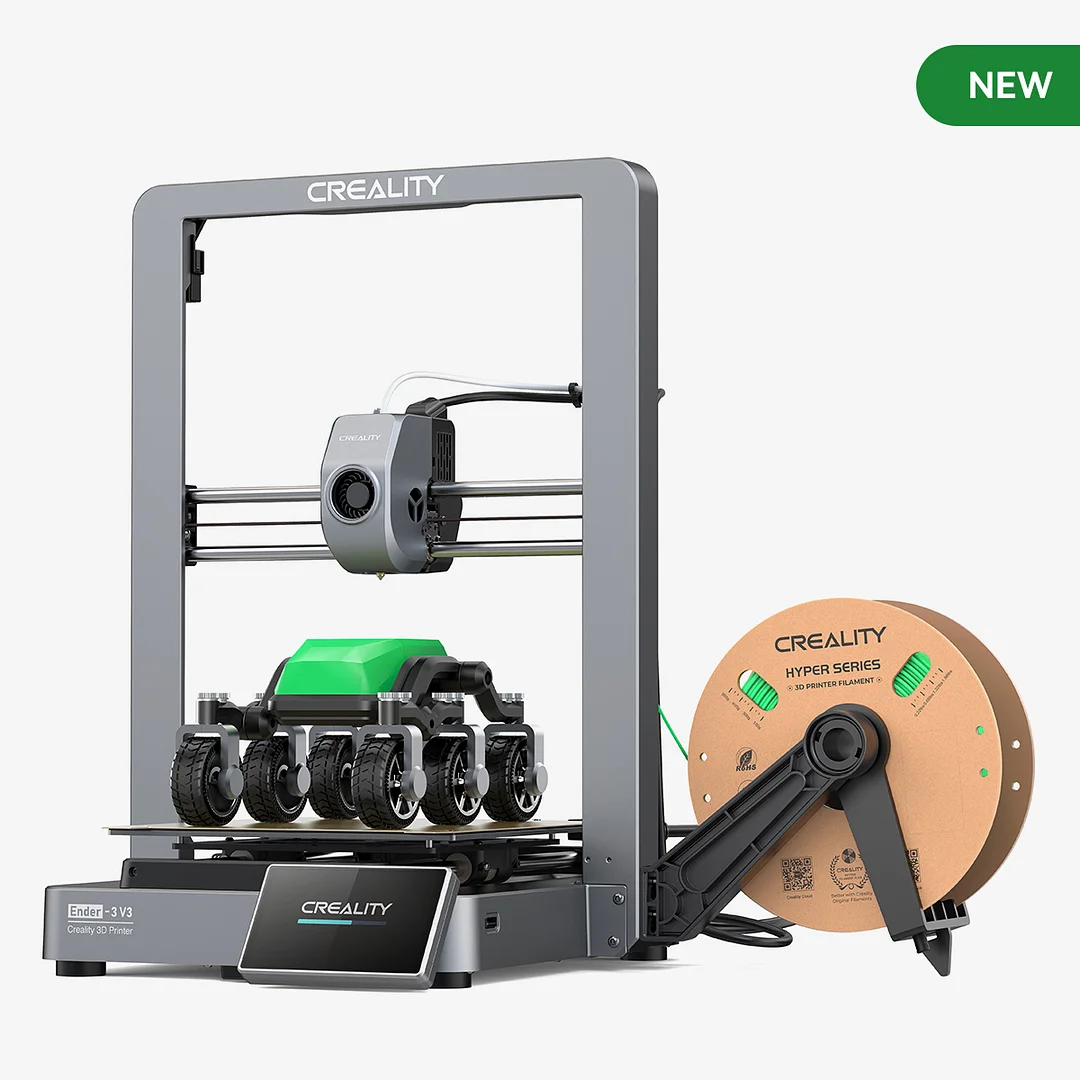

| Model | Ender 3 V3[BUY Ender 3 V3] |

H2D |

| Printing Material | Filament | Filament |

| Buy Filament for Creality Ender 3 V3 | Buy Filament forBambu Lab H2D | |

| Estimated price | $389,00 | $1899,00 |

| Manufacturer | Creality | Bambu Lab |

| Release Year | 2024 | 2025 |

| Print Volume [mm] | 220x220x250 | 350x320x325 |

| Printer Size [mm] | 358x374x498 | 492x514x626 |

| Weight [kg] | 7,12 | 42,3 |

| Power Loss Recovery | YES | YES |

| Enclosed printer | NO | YES |

| Bed Leveling | Automatic | Automatic |

| Filament End Sensor | YES | YES |

| Bed type | Heated | Heated |

| Power supply system | Direct Drive | Direct Drive |

| Standard nozzle | 0,4 | 0,4 |

| Maximum Nozzle Temperature [°C] | 300 | 350 |

| Maximum Bed Temperature [°C] | 110 | 120 |

| Maximum printing speed [mm/s] | 600 | 600 |

| Filament holder | YES | YES |

| Camera for supervision | NO | NO |

| Recommended filaments | PLA, PETG e TPU (95A+) | PLA, PETG, ABS, ASA, TPU, PVA, Nylon (PA) |

| Recommended slicers | Creality Print, Cura 5.0 ou superior, Prusa Slicer e Simplify3D | Bambu Studio |

| Maximum Resolution [mm] | 0,01 | 0,01 |

| Processor | 32 Bits | |

| Display | 4.3" HD touch screen | Touchscreen 5'' |

| Power Supply | 350 W | |

| Connectivity | USB drive, LAN, Creality Cloud APP | Wifi, Bambu bus, Cartão SD |

| Operating systems | Windows, Linux, Macbook | Windows, Mac, Linux |

| Date of registration in the system | 2024-03-01 | 2025-03-31 |

| Release date | 2024 | 2025 |

| Extra features | The Ender 3 V3 redefines 3D printing with its CoreXZ system, reaching speeds of up to 600mm/s, and stable metal construction with cast parts. It stands out for its powerful direct extrusion, quick-change tri-metal nozzle, and two powerful fans for instant cooling. Equipped with automatic calibration, it makes leveling and adjustments easy, promoting a fast and reliable printing experience with various materials. | Bambu Labs H2D combines high-speed 3D printing with a chamber heated up to 65 °C, dual extrusion with automatic nozzle switching, an AMS for filament drying and exchange, and AI sensors that detect failures. It offers optional laser and digital cutting capabilities, features intelligent calibration through computer vision, vibration control, enhanced fire safety, and real-time camera monitoring. |

| Support for multiple colors and materials (AMS and CFS) | NO | YES |

Notes * |

||

| Cost-benefit | 7 / 10 | 7 / 10 |

| Hardware | 3.2 / 10 | 7.2 / 10 |

| Tela | . | . |

| Print volume | 3 / 10 | 4 / 10 |

| Performance | 5 / 10 | 5 / 10 |

| [BUY Ender 3 V3] |

Conclusion |

| In concluding the comparison between the Creality Ender 3 V3 and the Bambu Lab H2D, it becomes clear that both printers cater to different user needs and budgets within the 3D printing space. The Ender 3 V3 stands out as an affordable option for hobbyists and enthusiasts, offering an excellent cost-to-performance ratio. With its automatic bed leveling, decent print volume, and compatibility with a variety of materials like PLA and PETG, it is a solid choice for users looking to dive into 3D printing without a hefty investment. The machine's reliable performance at a more accessible price point makes it a great entry-level printer. On the other hand, the H2D, while significantly more expensive, brings advanced features that would appeal to professionals or serious creators. With a larger print volume, dual extrusion capabilities, and intelligent failure detection, the H2D enhances productivity and expands creative possibilities. Its enclosed design and higher maximum bed and nozzle temperatures also allow for a wider range of materials, making it a versatile option for complex projects. Ultimately, the choice between these two models hinges on the user's specific requirements. The Ender 3 V3 is ideal for those starting their 3D printing journey or looking for budget-friendly options, while the H2D is geared toward more experienced users seeking advanced functionality and higher throughput capabilities. Customers should evaluate their individual needs and budget constraints to make the best decision suited to their 3D printing goals. |