Compare Ender 3 V3 vs A1

Comparison between the best 3D printers

Choose the best 3D printer at the best price. The cheapest 3D printers are here.

Buy a 3D printer here with 3D Fila.

|

|

|

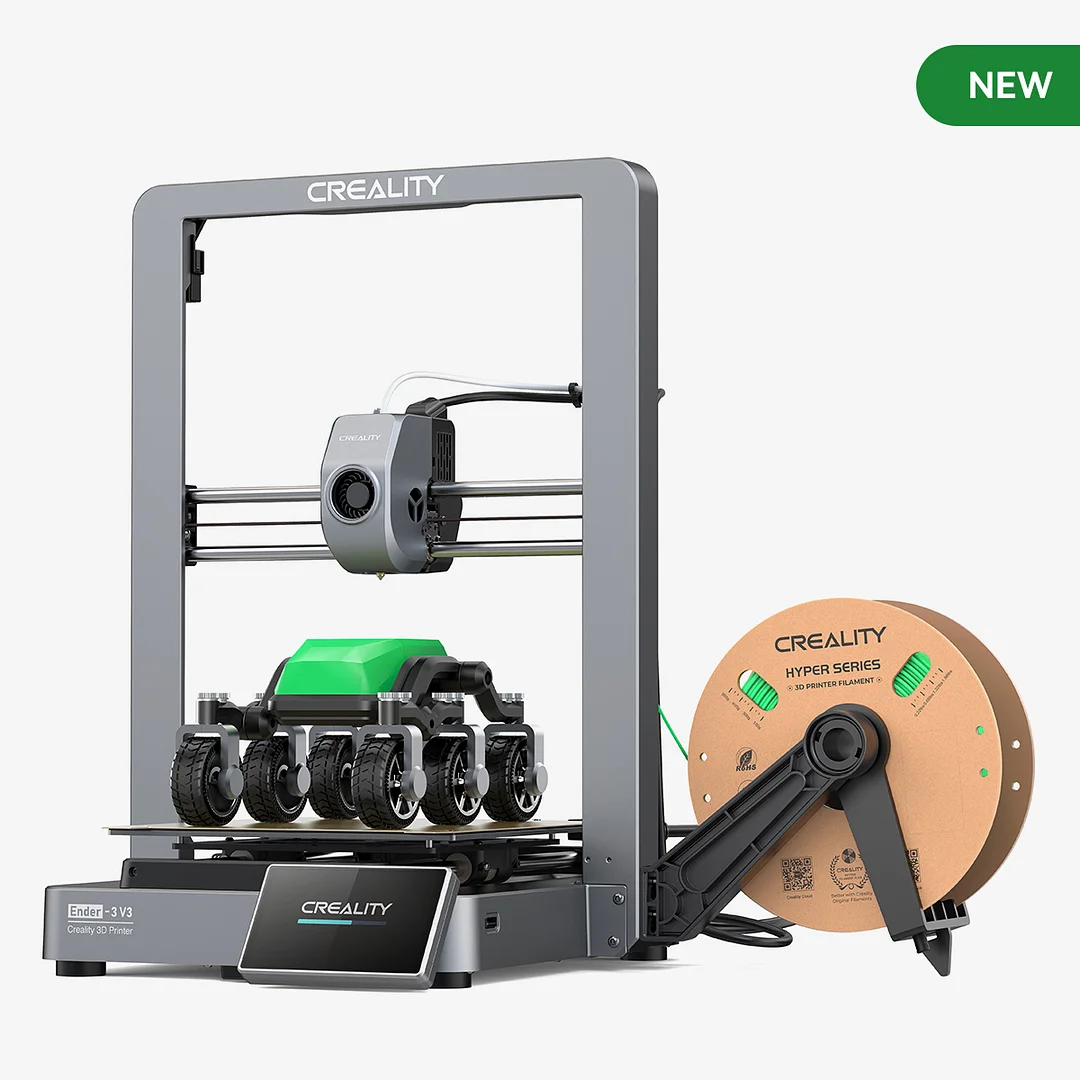

| Model | Ender 3 V3[BUY Ender 3 V3] |

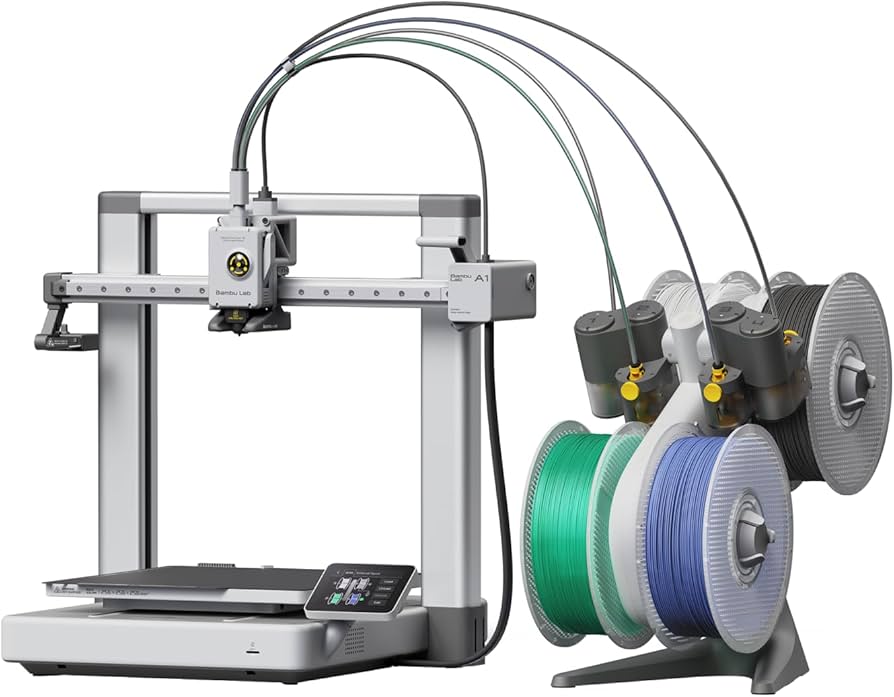

A1[BUY A1] |

| Printing Material | Filament | Filament |

| Buy Filament for Creality Ender 3 V3 | Buy Filament forBambu Lab A1 | |

| Estimated price | $389,00 | $700,00 |

| Manufacturer | Creality | Bambu Lab |

| Release Year | 2024 | 2023 |

| Print Volume [mm] | 220x220x250 | 256x256x256 |

| Printer Size [mm] | 358x374x498 | 385x410x430 |

| Weight [kg] | 7,12 | 8,3 |

| Power Loss Recovery | YES | YES |

| Enclosed printer | NO | NO |

| Bed Leveling | Automatic | Automatic |

| Filament End Sensor | YES | YES |

| Bed type | Heated | Heated |

| Power supply system | Direct Drive | Direct Drive |

| Standard nozzle | 0,4 | 0,4 |

| Maximum Nozzle Temperature [°C] | 300 | 300 |

| Maximum Bed Temperature [°C] | 110 | 100 |

| Maximum printing speed [mm/s] | 600 | 500 |

| Filament holder | YES | YES |

| Camera for supervision | NO | NO |

| Recommended filaments | PLA, PETG e TPU (95A+) | PLA, PETG, TPU, PVA |

| Recommended slicers | Creality Print, Cura 5.0 ou superior, Prusa Slicer e Simplify3D | SuperSlicer, PrusaSlicer, Cura, OrcaSlicer |

| Maximum Resolution [mm] | 0,01 | 0,1 |

| Processor | 32 Bits | |

| Display | 4.3" HD touch screen | Touchscreen 3,5 |

| Power Supply | 350 W | 350 W |

| Connectivity | USB drive, LAN, Creality Cloud APP | Wi-Fi, Bambu-Bus, Cartão Micro SD |

| Operating systems | Windows, Linux, Macbook | Windows, Linux, Macbook |

| Date of registration in the system | 2024-03-01 | 2024-07-17 |

| Release date | 2024 | 2023 |

| Extra features | The Ender 3 V3 redefines 3D printing with its CoreXZ system, reaching speeds of up to 600mm/s, and stable metal construction with cast parts. It stands out for its powerful direct extrusion, quick-change tri-metal nozzle, and two powerful fans for instant cooling. Equipped with automatic calibration, it makes leveling and adjustments easy, promoting a fast and reliable printing experience with various materials. | The BambuLab A1 printer features fully automatic calibration, multi-color printing with the AMS system, active flow rate compensation, quick nozzle change with a clip, active motor noise cancellation, a build volume of 256x256x256 mm³, a maximum extruder temperature of 300°C, and a heated bed of up to 100°C. In addition, it has high precision, a machine health management system and an intuitive 3.5-inch touchscreen interface. |

| Support for multiple colors and materials (AMS and CFS) | NO | YES |

Notes * |

||

| Cost-benefit | 7 / 10 | 7 / 10 |

| Hardware | 3.6 / 10 | 4.8 / 10 |

| Tela | . | . |

| Print volume | 3 / 10 | 4 / 10 |

| Performance | 5 / 10 | 4 / 10 |

| [BUY Ender 3 V3] | [BUY A1] |

Conclusion |

| In comparing the Creality Ender 3 V3 and the Bambu Lab A1 3D printers, several key factors emerge that can help potential buyers make an informed decision. The Ender 3 V3 offers a more budget-friendly entry point, making it an attractive option for hobbyists or those new to 3D printing. Despite its lower cost, it still features impressive specifications such as a maximum printing speed of 600 mm/s and a robust build quality. The printer’s automatic bed leveling, filament end sensor, and stable metal construction further enhance its user-friendliness while accommodating a variety of materials. On the other hand, the Bambu Lab A1, while higher in price, introduces advanced features such as multi-color printing capability, active flow rate compensation, and a more substantial print volume. Its fully automatic calibration and sophisticated touchscreen interface streamline operations for users looking for a more versatile and high-performance machine. While it doesn’t offer a significant speed advantage over the Ender 3 V3, it excels in precision and user experience. Ultimately, the choice between the Ender 3 V3 and the Bambu Lab A1 hinges on user priorities—whether a more economical, reliable, and straightforward printer is preferred versus a feature-rich model that offers versatility for more advanced printing tasks. Both printers present strong cost-benefit ratios and have their own unique strengths, catering to different segments of the 3D printing community. |