Compare Comgrow T500 vs Ender 6

Comparison between the best 3D printers

Choose the best 3D printer at the best price. The cheapest 3D printers are here.

Buy a 3D printer here with 3D Fila.

|

|

|

| Model | Comgrow T500 |

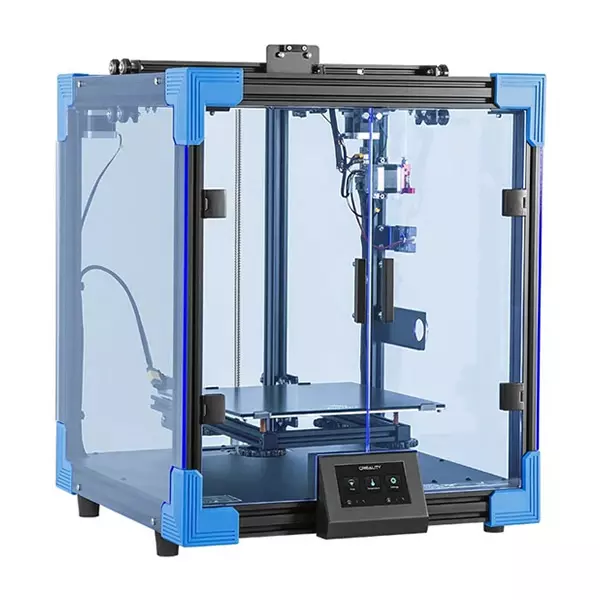

Ender 6[BUY Ender 6] |

| Printing Material | Filament | Filament |

| Buy Filament for Sovol Comgrow T500 | Buy Filament forCreality 3D Ender 6 | |

| Estimated price | $799,00 | $499,00 |

| Manufacturer | Sovol | Creality 3D |

| Release Year | 2024 | 2020 |

| Print Volume [mm] | 500x500x500 | 250x250x400 |

| Printer Size [mm] | 817x810x962 | 495x495x650 |

| Weight [kg] | 39 | 22 |

| Power Loss Recovery | YES | YES |

| Enclosed printer | NO | YES |

| Bed Leveling | Automatic | Manual |

| Filament End Sensor | YES | YES |

| Bed type | Heated | Heated |

| Power supply system | Direct Drive | Bowden |

| Standard nozzle | 0,4 | 0,4 |

| Maximum Nozzle Temperature [°C] | 300 | 260 |

| Maximum Bed Temperature [°C] | 80 | 100 |

| Maximum printing speed [mm/s] | 500 | 150 |

| Filament holder | YES | YES |

| Camera for supervision | NO | NO |

| Recommended filaments | PLA, PETG, Fibra de Carbono, TPU | PLA, TPU, ABS, PETG |

| Recommended slicers | Creality Print, Cura 5.0 ou superior, Prusa Slicer, Orca | Cura, Simplify, Slic3r |

| Maximum Resolution [mm] | 0,1 | 0,1 |

| Processor | 32 bits | |

| Display | 7'' IPS touchscreen, 60Hz | Touchscreen TFT 4,3'' |

| Power Supply | 500 W | 24V / 504W |

| Connectivity | SD / USB | |

| Operating systems | Windows, Mac, Linux | |

| Date of registration in the system | 2024-07-18 | 2021-04-15 |

| Release date | 2024 | 2020 |

| Extra features | The Sovol Comgrow T500 stands out for its large print volume of 500x500x500 mm, ideal for large-scale projects. It has a direct extruder with a gear ratio of 6.5:1, speeds of up to 200 mm/s, and high-performance motors. The 7" touchscreen with Klipper software makes navigation easy. The 49-point automatic leveling ensures a perfect first layer. It also has a full metal hotend at 300°C, linear rails on all axes, and WiFi connectivity. | The Creality Ender 6 stands out in the world of 3D printers with its CoreXY system, offering fast and high-quality prints. With a robust design, it has acrylic panels to protect against air currents, optimizing the printing of materials that require higher temperatures. It features a generic Creality hotend, effective up to ~240°C. Its differentials include 10mm GATES belts, promoting stability at high speeds, and a 360W power supply for reliable performance. The machine also has an intuitive user interface through a 4.3-inch touchscreen. |

| Support for multiple colors and materials (AMS and CFS) | NO | NO |

Notes * |

||

| Cost-benefit | 7 / 10 | 7 / 10 |

| Hardware | 3.6 / 10 | 2.5 / 10 |

| Tela | . | . |

| Print volume | 5 / 10 | 4 / 10 |

| Performance | 4 / 10 | 1 / 10 |

| [BUY Ender 6] |

Conclusion |

| In comparing the Comgrow T500 and the Creality Ender 6, several factors must be considered to determine the best 3D printer for potential buyers. The Comgrow T500 is positioned as a high-performance option with a larger print volume and advanced features. It supports a variety of filaments and boasts an impressive maximum printing speed and resolution. Its automatic bed leveling and direct drive system enhance usability and print quality, making it ideal for large projects or more complex prints. Additionally, the modern touchscreen interface and WiFi connectivity offer a more user-friendly experience. In contrast, the Ender 6 is a more affordable model that delivers reliable performance with a focus on print stability and quality thanks to its CoreXY system and robust design. It offers a smaller print volume but remains a solid choice for hobbyists and casual users who don't require the extensive capabilities of the T500. The Ender 6's manual bed leveling and lower maximum temperature might be limitations for users looking to experiment with a wider range of materials. Ultimately, the choice between these two printers should be guided by budget and specific printing needs. The Comgrow T500 presents a stronger value for those seeking versatility and larger capacity, while the Ender 6 serves as a practical option for those looking to enter the 3D printing space without a significant investment. Each has its strengths, making them suitable for different types of users and projects. |