Compare Comgrow T500 vs A3V3

Comparison between the best 3D printers

Choose the best 3D printer at the best price. The cheapest 3D printers are here.

Buy a 3D printer here with 3D Fila.

|

|

|

| Model | Comgrow T500 |

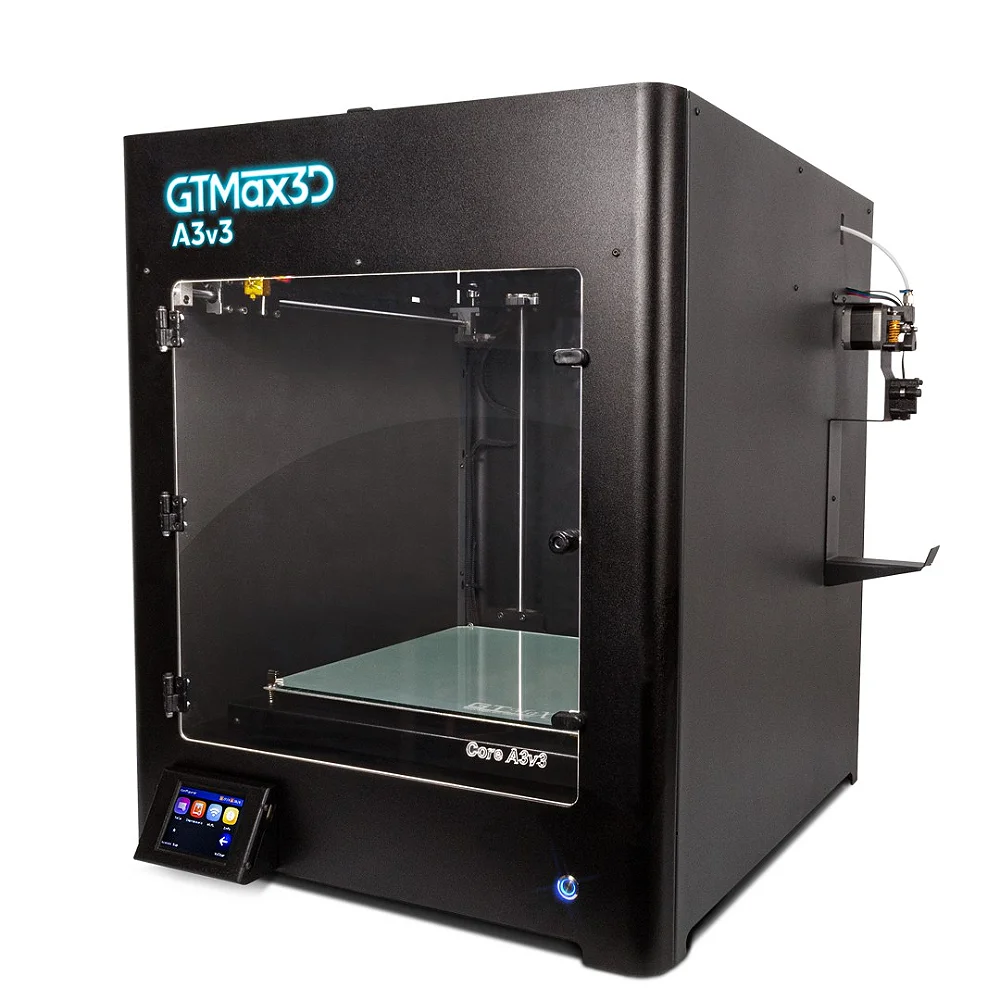

A3V3 |

| Printing Material | Filament | Filament |

| Buy Filament for Sovol Comgrow T500 | Buy Filament forGTMax A3V3 | |

| Estimated price | $799,00 | $1210,00 |

| Manufacturer | Sovol | GTMax |

| Release Year | 2024 | 2022 |

| Print Volume [mm] | 500x500x500 | 320x320x340 |

| Printer Size [mm] | 817x810x962 | 640x580x630 |

| Weight [kg] | 39 | |

| Power Loss Recovery | YES | YES |

| Enclosed printer | NO | YES |

| Bed Leveling | Automatic | Automatic |

| Filament End Sensor | YES | YES |

| Bed type | Heated | Heated |

| Power supply system | Direct Drive | Bowden |

| Standard nozzle | 0,4 | 0,4 |

| Maximum Nozzle Temperature [°C] | 300 | 295 |

| Maximum Bed Temperature [°C] | 80 | |

| Maximum printing speed [mm/s] | 500 | 180 |

| Filament holder | YES | YES |

| Camera for supervision | NO | NO |

| Recommended filaments | PLA, PETG, Fibra de Carbono, TPU | PLA, PETG |

| Recommended slicers | Creality Print, Cura 5.0 ou superior, Prusa Slicer, Orca | Cura, Simplify, Slic3r, IdeaMaker e outros |

| Maximum Resolution [mm] | 0,1 | 0,05 |

| Processor | ||

| Display | 7'' IPS touchscreen, 60Hz | Display touchscreen 3,2'' |

| Power Supply | 500 W | |

| Connectivity | SD / USB / Wi-Fi | |

| Operating systems | Windows, Mac, Linux | |

| Date of registration in the system | 2024-07-18 | 2022-11-12 |

| Release date | 2024 | 2022 |

| Extra features | The Sovol Comgrow T500 stands out for its large print volume of 500x500x500 mm, ideal for large-scale projects. It has a direct extruder with a gear ratio of 6.5:1, speeds of up to 200 mm/s, and high-performance motors. The 7" touchscreen with Klipper software makes navigation easy. The 49-point automatic leveling ensures a perfect first layer. It also has a full metal hotend at 300°C, linear rails on all axes, and WiFi connectivity. | The PROCORE A3v3 is an advanced 3D printer with a robust structure and Wi-Fi connectivity. It stands out for its aluminum extruder with Dual Gear system for precision and traction, and a movement system with machined parts. It includes a 3.2-inch LCD Touchscreen Display, Wi-Fi remote control and a Core XY movement system for greater speed and precision. It offers an Allmetal Volcano hotend that reaches up to 295°C, is compatible with various filaments and has an energy saving system, reducing consumption by up to 75%. |

| Support for multiple colors and materials (AMS and CFS) | NO | NO |

Notes * |

||

| Cost-benefit | 7 / 10 | 6 / 10 |

| Hardware | 3.6 / 10 | 3.5 / 10 |

| Tela | . | . |

| Print volume | 5 / 10 | 4 / 10 |

| Performance | 4 / 10 | 1 / 10 |

Conclusion |

| In conclusion, the comparison between the Comgrow T500 and the GTMax A3V3 highlights significant differences in their features and performance, ultimately guiding potential buyers based on their needs and budget. The Comgrow T500 stands out with its considerable print volume of 500x500x500 mm, coupled with impressive printing speeds and a user-friendly 7-inch touchscreen interface. Its cost-effective pricing and comprehensive features, such as automatic bed leveling and high maximum nozzle temperature, make it an excellent choice for users focused on larger projects and versatile material handling. With a score of 8/10 for cost-benefit and performance, it clearly caters to those who prioritize functionality without overspending. In contrast, the GTMax A3V3, while offering a more compact print size, is designed with advanced features such as a dual gear extruder for better filament traction and a core XY movement system for improved precision. However, its higher price point and lower performance ratings suggest it may appeal more to users seeking a specific type of precision and build quality, rather than sheer volume. Ultimately, if large-scale printing and cost-efficiency are priorities, the Comgrow T500 emerges as the winner, whereas the GTMax A3V3 may be better suited for those willing to invest more for improved build precision and hardware quality. The choice between these two will largely depend on individual requirements, budget constraints, and specific use cases in the realm of 3D printing. |