Compare CR5 PRO H vs Ender 3 V3

Comparison between the best 3D printers

Choose the best 3D printer at the best price. The cheapest 3D printers are here.

Buy a 3D printer here with 3D Fila.

|

|

|

| Model | CR5 PRO H[BUY CR5 PRO H] |

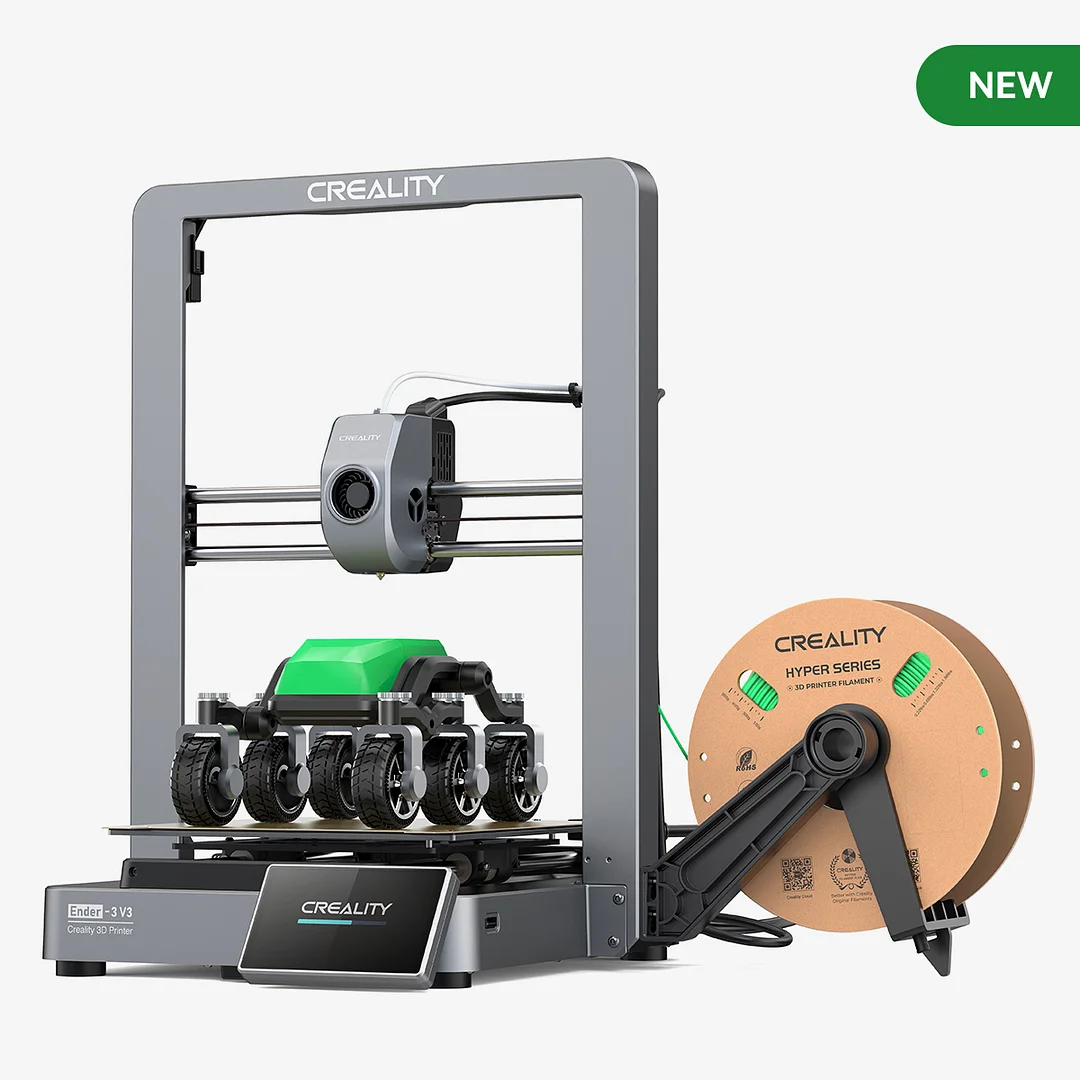

Ender 3 V3[BUY Ender 3 V3] |

| Printing Material | Filament | Filament |

| Buy Filament for Creality 3D CR5 PRO H | Buy Filament forCreality Ender 3 V3 | |

| Estimated price | $1300,00 | $389,00 |

| Manufacturer | Creality 3D | Creality |

| Release Year | 2022 | 2024 |

| Print Volume [mm] | 300x225x380 | 220x220x250 |

| Printer Size [mm] | 530x487x612 | 358x374x498 |

| Weight [kg] | 32,5 | 7,12 |

| Power Loss Recovery | YES | YES |

| Enclosed printer | YES | NO |

| Bed Leveling | Automatic | Automatic |

| Filament End Sensor | YES | YES |

| Bed type | Heated | Heated |

| Power supply system | Bowden | Direct Drive |

| Standard nozzle | 0,4 | 0,4 |

| Maximum Nozzle Temperature [°C] | 300 | 300 |

| Maximum Bed Temperature [°C] | 100 | 110 |

| Maximum printing speed [mm/s] | 100 | 600 |

| Filament holder | YES | YES |

| Camera for supervision | NO | NO |

| Recommended filaments | PLA, PETG, Tritan, Flex, ABS | PLA, PETG e TPU (95A+) |

| Recommended slicers | Cura, Simplify, Slic3r, IdeaMaker | Creality Print, Cura 5.0 ou superior, Prusa Slicer e Simplify3D |

| Maximum Resolution [mm] | 0,1 | 0,01 |

| Processor | ATMEGA 2560 | 32 Bits |

| Display | Display touchscreen 4,3'' | 4.3" HD touch screen |

| Power Supply | 110/220V / 350W | 350 W |

| Connectivity | SD / USB | USB drive, LAN, Creality Cloud APP |

| Operating systems | Windows, Mac, Linux | Windows, Linux, Macbook |

| Date of registration in the system | 2022-11-04 | 2024-03-01 |

| Release date | 2022 | 2024 |

| Extra features | The Creality CR-5 PRO H 3D Printer stands out with a high-temperature nozzle (up to 300°C), a 300 x 225 x 380mm print volume, and a closed chamber for thermal stability. It includes BLTouch auto-leveling, a carbon-crystal silica glass base for easy model grip and removal, a filament sensor, and a resume print function. It has a 4.3-inch touchscreen interface, quiet operation, an attractive design, and is pre-assembled, ideal for technical materials. | The Ender 3 V3 redefines 3D printing with its CoreXZ system, reaching speeds of up to 600mm/s, and stable metal construction with cast parts. It stands out for its powerful direct extrusion, quick-change tri-metal nozzle, and two powerful fans for instant cooling. Equipped with automatic calibration, it makes leveling and adjustments easy, promoting a fast and reliable printing experience with various materials. |

| Support for multiple colors and materials (AMS and CFS) | NO | NO |

Notes * |

||

| Cost-benefit | 6 / 10 | 7 / 10 |

| Hardware | 3 / 10 | 3.2 / 10 |

| Tela | . | . |

| Print volume | 4 / 10 | 3 / 10 |

| Performance | 1 / 10 | 5 / 10 |

| [BUY CR5 PRO H] | [BUY Ender 3 V3] |

Conclusion |

| In conclusion, the comparison between the Creality CR-5 PRO H and the Ender 3 V3 highlights distinct strengths and weaknesses of both 3D printers, catering to different user needs and budget considerations. The CR-5 PRO H excels in build volume, with a larger print area and an enclosed structure that enhances thermal stability, making it ideal for printing more complex and technical materials. Its higher nozzle temperature capability and advanced features such as a carbon-crystal silica glass base and auto-leveling add to its appeal for serious hobbyists and professional users. On the other hand, the Ender 3 V3 offers exceptional performance with significantly higher maximum printing speeds and a very competitive price point, making it an attractive option for users looking to balance quality and affordability. This printer's lightweight build and direct drive extruder contribute to ease of use, especially for a range of filaments, while its rapid operation and automatic calibration features cater well to beginners and casual users. While the CR-5 PRO H presents a solid but higher-cost option for users who prioritize advanced specifications and larger capabilities, the Ender 3 V3 stands out as a cost-effective choice for those who seek reliable performance without the need for extensive printing volume or specialized materials. Ultimately, the decision between the two will depend on the user’s specific requirements and budget constraints, making both models valuable contenders in the growing 3D printing market. |