Compare CR10 SE vs SV06

Comparison between the best 3D printers

Choose the best 3D printer at the best price. The cheapest 3D printers are here.

Buy a 3D printer here with 3D Fila.

|

|

|

| Model | CR10 SE |

SV06 |

| Printing Material | Filament | Filament |

| Buy Filament for Creality CR10 SE | Buy Filament forSovol SV06 | |

| Estimated price | $386,00 | $259,00 |

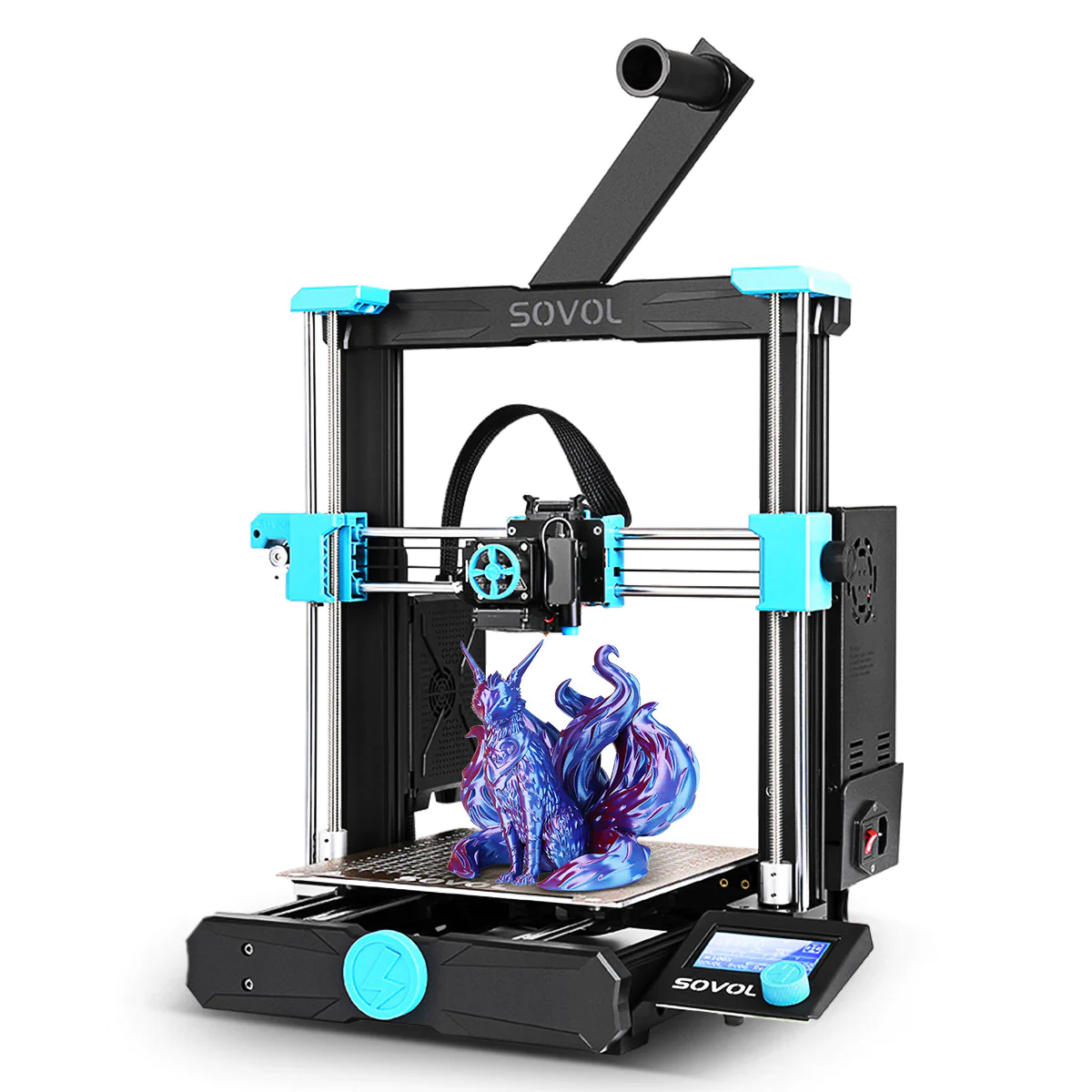

| Manufacturer | Creality | Sovol |

| Release Year | 2023 | 2022 |

| Print Volume [mm] | 220x220x265 | 220x220x250 |

| Printer Size [mm] | 490x470x625 | 497x388x610 |

| Weight [kg] | 6,9 | 9 |

| Power Loss Recovery | NO | YES |

| Enclosed printer | NO | NO |

| Bed Leveling | Automatic | |

| Filament End Sensor | NO | NO |

| Bed type | Heated | |

| Power supply system | Direct Drive | Direct Drive |

| Standard nozzle | 0,4 | 0,4 |

| Maximum Nozzle Temperature [°C] | 300 | 300 |

| Maximum Bed Temperature [°C] | 110 | 100 |

| Maximum printing speed [mm/s] | 600 | 80 |

| Filament holder | YES | NO |

| Camera for supervision | YES | YES |

| Recommended filaments | PLA, PETG, PET, TPU, PA Wood, ABS, ASA, PA, PLA-CF | PLA, PETG, Tritan, Flex, ABS |

| Recommended slicers | Creality Print, Cura, Simplify3D, PrusaSlicer, Orca Slice | Cura, Simplify, Slic3r, IdeaMaker |

| Maximum Resolution [mm] | 0,1 | 0,1 |

| Processor | ||

| Display | Mono | |

| Power Supply | ||

| Connectivity | USB, Wifi | SD / USB |

| Operating systems | Windows, Linux, Macbook | Windows, Mac, Linux |

| Date of registration in the system | 2024-07-02 | 2023-03-02 |

| Release date | 2023 | 2022 |

| Extra features | The Creality CR10 SE stands out for its printing speed of up to 600 mm/s, easy and intuitive assembly, direct extruder with double gears, hotend with hardened steel nozzle and ceramic heater, automatic leveling with CR-Touch and pressure sensor, and use of Creality OS firmware based on Klipper, with automatic input shaping calibration. It also includes Wi-Fi connectivity, a filament out-of-stock sensor and a robust structure with linear rails on the X and Y axes. | The Sovol SV06 printer stands out for having a direct-drive extruder, providing better performance when printing a variety of materials. It has linear rods for greater precision and smoothness in movements, as well as an automatic bed leveling system, eliminating manual adjustments. Its all-metal hotend supports a wide range of materials. The SV06 also features sensorless homing and Z-axis self-alignment, increasing reliability and ease of use. Compatible with Klipper software, it offers the possibility of upgrades to increase printing speed. |

| Support for multiple colors and materials (AMS and CFS) | NO | NO |

Notes * |

||

| Cost-benefit | 7 / 10 | 6 / 10 |

| Hardware | 2.4 / 10 | 0.7 / 10 |

| Tela | . | . |

| Print volume | 3 / 10 | 3 / 10 |

| Performance | 5 / 10 | 0 / 10 |

Conclusion |

| In comparing the Creality CR10 SE and the Sovol SV06, several factors highlight the strengths and weaknesses of each printer, particularly in terms of performance, features, and value for money. The Creality CR10 SE, while at a higher price point, boasts superior printing speed, achieving up to 600 mm/s, and incorporates advanced features such as automatic bed leveling, a robust structure, and improved connectivity options like Wi-Fi. Its generous range of compatible materials and reliability in performance make it a well-rounded machine for those looking to delve deeper into 3D printing. On the other hand, the Sovol SV06, released slightly earlier, offers a more budget-friendly option. It emphasizes precision and ease of use with features such as an automatic bed leveling system and a direct-drive extruder. However, its lower print speed and limited material compatibility may restrict its versatility compared to the CR10 SE. Ultimately, the choice between these two printers depends largely on user needs and budget. The CR10 SE provides a more comprehensive feature set and performance capabilities, making it ideal for serious users or those planning to engage in diverse printing projects. In contrast, the Sovol SV06 stands as a capable entry-level option for budget-conscious individuals or beginners, although it may lack some advanced functionalities that enhance the 3D printing experience. Users must weigh these considerations against their specific requirements to make an informed decision. |