Compare A1 vs KP3S PRO V2

Comparison between the best 3D printers

Choose the best 3D printer at the best price. The cheapest 3D printers are here.

Buy a 3D printer here with 3D Fila.

|

|

|

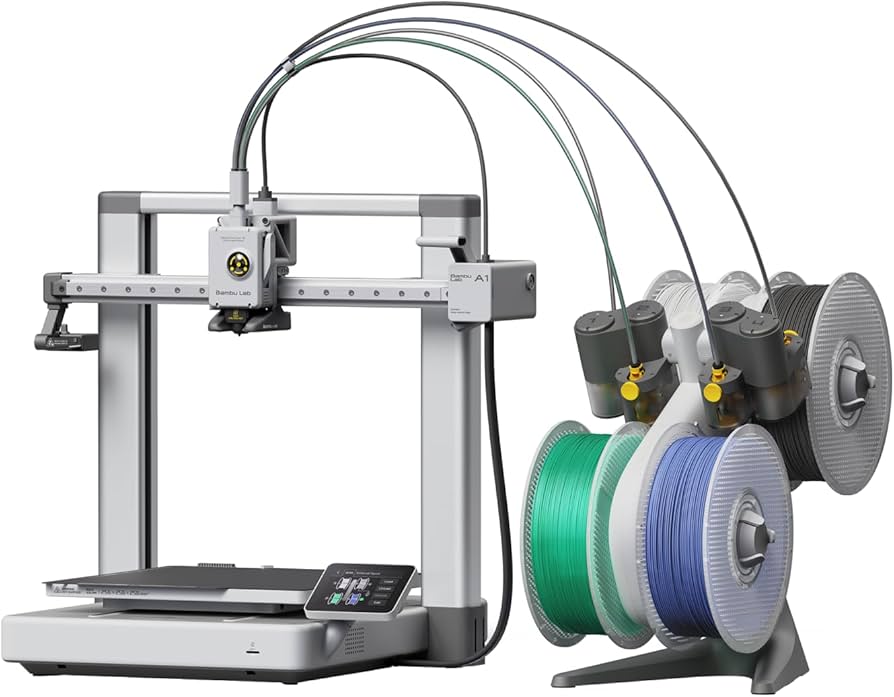

| Model | A1[BUY A1] |

KP3S PRO V2 |

| Printing Material | Filament | Filament |

| Buy Filament for Bambu Lab A1 | Buy Filament forKingroon KP3S PRO V2 | |

| Estimated price | $700,00 | $229,00 |

| Manufacturer | Bambu Lab | Kingroon |

| Release Year | 2023 | 2024 |

| Print Volume [mm] | 256x256x256 | 220x220x250 |

| Printer Size [mm] | 385x410x430 | 420x400x450 |

| Weight [kg] | 8,3 | 12,6 |

| Power Loss Recovery | YES | NO |

| Enclosed printer | NO | NO |

| Bed Leveling | Automatic | Automatic |

| Filament End Sensor | YES | NO |

| Bed type | Heated | Heated |

| Power supply system | Direct Drive | Direct Drive |

| Standard nozzle | 0,4 | 0,4 |

| Maximum Nozzle Temperature [°C] | 300 | 260 |

| Maximum Bed Temperature [°C] | 100 | 100 |

| Maximum printing speed [mm/s] | 500 | 350 |

| Filament holder | YES | YES |

| Camera for supervision | YES | YES |

| Recommended filaments | PLA, PETG, TPU, PVA | PLA, PETG, TPU |

| Recommended slicers | SuperSlicer, PrusaSlicer, Cura, OrcaSlicer | Cura, Orca Slicer |

| Maximum Resolution [mm] | 0,1 | 0,01 |

| Processor | ||

| Display | Touchscreen 3,5 | LCD Mono |

| Power Supply | 350 W | 300 W |

| Connectivity | Wi-Fi, Bambu-Bus, Cartão Micro SD | USB-C / MicroSD / Ethernet |

| Operating systems | Windows, Linux, Macbook | Windows, Mac, Linux |

| Date of registration in the system | 2024-07-17 | 2025-03-18 |

| Release date | 2023 | 2024 |

| Extra features | The BambuLab A1 printer features fully automatic calibration, multi-color printing with the AMS system, active flow rate compensation, quick nozzle change with a clip, active motor noise cancellation, a build volume of 256x256x256 mm³, a maximum extruder temperature of 300°C, and a heated bed of up to 100°C. In addition, it has high precision, a machine health management system and an intuitive 3.5-inch touchscreen interface. | The Kingroon KP3S Pro V2 is a high-speed FDM 3D printer with Klipper firmware, ensuring fast and precise prints. It features linear rails on all axes, a Direct Drive extruder with a 9.5:1 gear ratio, and an efficient ceramic heater. It includes an inductive sensor for automatic bed leveling, a PEI magnetic bed, a built-in accelerometer for vibration calibration, and Wi-Fi, Ethernet, and USB connectivity for remote control. |

| Support for multiple colors and materials (AMS and CFS) | YES | NO |

Notes * |

||

| Cost-benefit | 7 / 10 | 7 / 10 |

| Hardware | 4.2 / 10 | 0.8 / 10 |

| Tela | . | . |

| Print volume | 4 / 10 | 3 / 10 |

| Performance | 4 / 10 | 3 / 10 |

| [BUY A1] |

Conclusion |

| In comparing the Bambu Lab A1 and the Kingroon KP3S PRO V2 3D printers, several key factors come into play, particularly in terms of features, performance, and cost-effectiveness. The Bambu Lab A1 stands out with its advanced specifications, including a higher maximum extruder temperature, larger print volume, and superior printing speed. It offers a range of intuitive features such as power loss recovery and an automatic filament end sensor, which enhance user convenience and printing reliability. Its touchscreen interface and support for multi-color printing further refine the user experience, making it a robust choice for those looking for cutting-edge technology and versatility. On the other hand, the Kingroon KP3S PRO V2, while more affordable, operates with slightly less capability in key areas such as maximum speed and temperature. It still delivers solid performance with its efficient Direct Drive setup and Klipper firmware, catering to those who prioritize speed and precision. Additionally, it offers essential features like automatic bed leveling and various connectivity options, appealing to users who require flexibility without breaking the bank. Ultimately, the decision comes down to individual needs and budget. The Bambu Lab A1 represents a premium investment geared towards enthusiasts seeking high performance and advanced features. In contrast, the Kingroon KP3S PRO V2 is an excellent choice for budget-conscious users who still want a reliable 3D printing experience. Both printers deliver a commendable blend of cost-benefit and hardware capabilities, allowing users to select based on their specific priorities in 3D printing. |